Starting, interrupting, canceling jobs

The workflow for restoration is as follows:

→

→

→

→

→

→

→

Overview

When you have prepared your jobs and your machine, you can start machining. Machining is a fully automated process and only requires your attention in case of unexpected events.

Do not move the machine during job execution, otherwise the results may become imprecise.

- Ensure the following:

- All required tools are in the right positions in the tool magazine and are neither worn nor damaged.

- There is enough cooling liquid in the cooling liquid tank.

- Close the working chamber door.

- .

Starting jobs via the touchscreen

Following you find the workflow for selecting, checking and executing jobs.

To open the Jobs section, select the depicted icon.

To open the Jobs section, select the depicted icon.- The Jobs section displays. The details of the next queued job display.

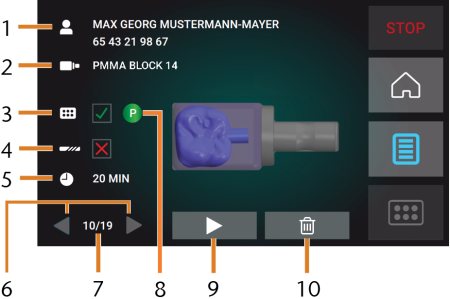

- Job name, patient information

- Required blank type

- Check box for the required tool magazine

- Check box for the tool life values

- Prospective job duration

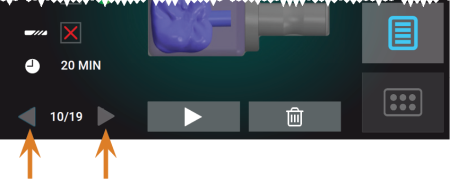

- Arrows to browse through the available jobs

- Number of current job / number of available jobs

- Color code of the required tool magazine

- Icon for starting the current job

- Icon for deleting the current job

- Use the arrows in the left bottom corner to select the desired job.

- Verify that the elements [2], [3], [4] display as required:

-

Make sure that the mounted blank corresponds to [2].

To start machining, select the depicted icon.

To start machining, select the depicted icon.- The following happens:

- If required, the working chamber door closes.

- The machine determines the size of the mounted block with the spindle. If the measured block size differs from the block size which is stored in the job file, a corresponding message displays on the touchscreen.

- If the machine determined a different block size, continue as follows:

- If the job was started, the following happens:

- The machine starts processing.

- The working chamber is illuminated in blue.

- The remaining machining duration displays on the touchscreen.

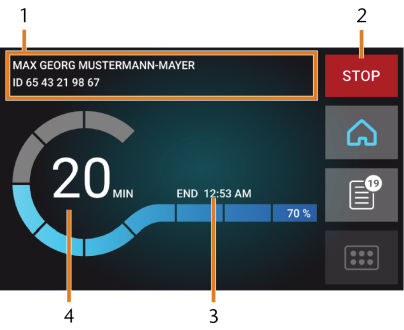

- Job name, patient information

- Icon for canceling the job

- Job end time

- Prospective remaining job duration

- If using exocad ChairsideCAD, do not shut down your CAD computer or disconnect it from the network until machining has finished. Otherwise, you may have to restart your machine and the job.

- Wait until the machine has finished.

- The working chamber door opens. The following dialog displays on the touchscreen.

- Remove the blank from the working chamber and check whether the job has been executed correctly.

If you are satisfied, select the depicted icon on the touchscreen.

If you are satisfied, select the depicted icon on the touchscreen.- The job is marked as finished and no longer displays in the Jobs section.

If you need to repeat the job, select the depicted icon on the touchscreen.

If you need to repeat the job, select the depicted icon on the touchscreen.- The job continues to display in the Jobs section. You can restart it as required.

- Leave the working chamber door open so that the working chamber can dry.

The remaining job duration is an estimation based on a self-learning function.

You can restore finished jobs with dentalcnc. Read the corresponding documentation for more details.

After machining, air is blown into the working chamber for some time to help dry the working chamber, which causes air noise. This does not indicate that there is a malfunction.

Aborting machining

You can cancel machining at any time. You need to restart the job with a new blank. You cannot continue the job with the used blank because the machine will not recognize this blank and you will receive an error message.

To cancel machining, select the depicted icon.

To cancel machining, select the depicted icon.- The machine prompts you to confirm the cancellation.

To confirm your choice, select the depicted icon.

To confirm your choice, select the depicted icon.- The spindle puts the tool which is currently in the collet chuck into the tool magazine. The working chamber door opens.

- If the working chamber is wet, leave the working chamber door open so that the working chamber can dry.

Job interruptions and job abortions

A job will be interrupted in the following cases:

- The compressed air supply is not sufficient

- The cooling liquid flow is not sufficient

An interrupted job will normally be continued automatically after the error is corrected.

A job will be aborted in the following cases:

- In case of a machine malfunction

- In case of a tool breakage

- In case of a power failure

If a job was aborted, you have to restart it.

You need to restart the job with a new blank. You cannot continue the job with the used blank because the machine will not recognize this blank and you will receive an error message.

How to proceed in the event of a job interruption

If the compressed air is insufficient

If the cooling liquid flow rate is insufficient

- Check if there is enough cooling liquid in the tank.

- Check if the cooling liquid and the tank including the filter are clean.