Mounting and removing blanks

The workflow for restoration is as follows:

→

→

→

→

→

→

→

The machine can process the following blanks:

- Blocks, max. size: 45 x 20 x 20 mm (L/D/H)

- Prefabricated abutments*

Extra equipment![]() Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

Mounting and removing blocks

You can mount blocks to the block holder where a collet chuck immobilizes them. The collet chuck opens and closes with the working chamber door.

- Open the working chamber door.

- The working chamber door is open. The collet chuck is open.

- Pull the block out of the holder if any.

- Check the collet chuck for dirt.

- If necessary, clean the collet chuck. Cleaning or exchanging the collet chuck of the spindle

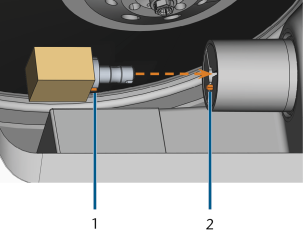

- Insert the required block into the collet chuck of the block holder: Align the groove [1] of the block with the positioning pin [2] of the block holder.

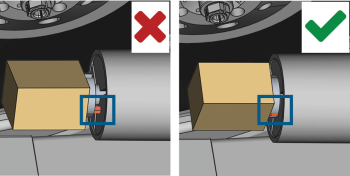

- Push the block into the block holder until it snaps into place. If the block does not snap into place, twist it until the positioning pin lies in the groove.

- Close the working chamber door.

- The working chamber door is closed. The collet chuck is closed. The block is mounted.