Release Notes DentalCAM & DentalCNC 8.01

What's new in DentalCAM and DentalCNC?

New functions | Improvement of an existing function | Bug Fixes

Highlights

Below you'll find the biggest new features of this release which will have the most impact in your workflow.

DentalCAM & DentalCNC

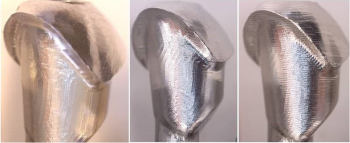

High speed strategies for Zirconia, PMMA and Wax – up to 30 % faster

Milling

Our new high speed strategies enable you to mill objects faster than ever with DentalCAM & DentalCNC.

Applies to:

-

Zirconia

-

Translucent Zirconia

-

PMMA

-

PMMA burn

-

Wax

Example: Objects made from zirconium oxide discs are milled up to 30% faster*.

Grinding

R5 / N4+: Zirconia and PMMA blocks are now ground up to 30% faster*.

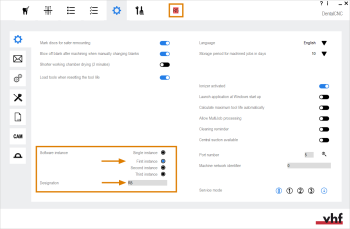

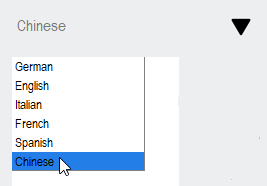

The user interface has been localized in Chinese

-

In the General application settings of both applications, select Chinese from the Language drop-down list.

Selecting Chinese as the user interface language

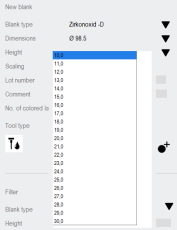

The material database can now be updated independently from DentalCAM & DentalCNC

Until now, the data of supported blank types (“material database”) was always updated together with a new DentalCAM & DentalCNC release. Now, the material database is separated from the application data so that it can be updated as soon as we make improvements.

If your CAM computer![]() is connected to the internet, DentalCNC will update the material database automatically.

is connected to the internet, DentalCNC will update the material database automatically.

(N4+) CAD/CAM integration available for exocad ChairsideCAD from Version 3.0

Nest objects directly in exocad ChairsideCAD and export them for machining with DentalCNC.

DentalCAM

Jobs are now loaded much faster

The time to load an existing job until you can edit it in the nesting view has been greatly decreased.

Improved surface quality and quality settings for titanium and cobalt chrome abutments

The parameters for the 3 quality settings have been optimized.

- The surface quality has been improved.

-

The gradation of the processing times is now better:

- Optimal faster

- Standard lies in the middle between the other 2 settings.

DentalCNC

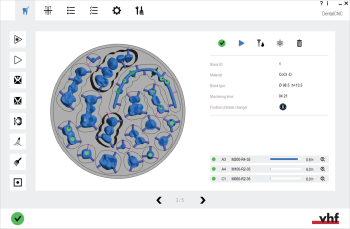

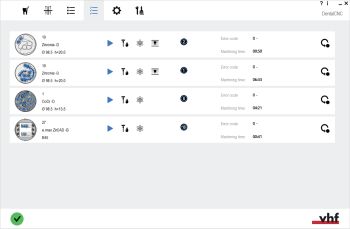

Revamped DentalCNC user interface for higher work efficiency

DentalCNC is a powerful tool with many features. So many in fact that we decided to present them in a better structured way.

Therefore, we revamped DentalCNC‘s user interface.

-

The new machining view allows you to focus on one job at a time and only shows relevant information and icons. You can switch between jobs at any time. [Read more]

-

In the new job list, you can reorder jobs and operate the blank changer

of corresponding machines. [Read more]

of corresponding machines. [Read more] -

The job archive lists all machined jobs and allows you to move them back to the job list. [Read more]

-

The program settings have been cleaned up: Options that were rarely used no longer take up valuable screen space. [Read more]

You can now distinguish individual instances of DentalCNC with color-highlighted text labels

If you use the multi machine control feature, you can now add color-highlighted text labels to DentalCNC‘s title bar

The labels will help you distinguish the instances of DentalCNC.

How to use the multi-machine control feature: Setting up multi-machine control

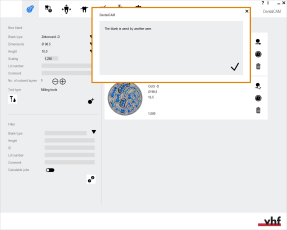

Improved stability when working with a shared blank archive

If you use a blank archive which is shared between several DentalCAM clients, you will now benefit from an improved stability of this feature.

DentalCAM will now also display a message, if you try to edit a blank that is opened in another DentalCAM client.

How to set up a shared blank archive: Integrating DentalCAM & DentalCNC into your network

Additional features and changes

DentalCAM & DentalCNC

Tool optimizations

We have optimized the use of tools for better processing results:

-

To improve the tool life when processing Zirconia, DentalCAM & DentalCNC now require diamond-coated tools for this material.

Therefore, the Use diamond-coated tools for Zirconia option has been removed from DentalCAM.

-

Only Z4: Machining composites now requires the diamond-coated tools C200–R1D–35 and C100–R1D–35.

-

For a tool overview, see Tool overview.

Cobalt chrome and titanium will now be machined with all 5 axes of corresponding machines

We improved our machining strategies for cobalt chrome and titanium so that 5-axis machines will now use all 5 axes for machining these materials.

DentalCAM

When importing STL files, you can now add labels that will be milled

In the Import view, you can now add a text label to each object that will be milled on the object.

-

More information on the calculation options: Specify the calculation options.

-

How to edit labels during nesting: Moving, editing and deleting label texts milled on objects

Sweden & Martina prefabricated abutments can now be used with the MEDENTIKA PreFace abutment holder

You can now use prefab abutments from Sweden & Martina with the MEDENTIKA PreFace abutment holder.

Individual machining is now the default tool usage sequence for cobalt chrome and titanium

To increase the process reliability when machining cobalt chrome and titanium, Individual processing is now the default tool usage sequence for these materials. This new default value corresponds to our machining recommendations.

Further background information:

Machining of bite splints on 5-axis-machines has been improved

When machining bite splints on 5-axis-machines, now less residual material remains.

DentalCAM will now warn you about large STL files

If you import a large STL file, DentalCAM will now display a warning message. To avoid long loading times, we recommend compressing large STL files or exporting them with optimized settings.

(Z4) Patient names entered in TRIOS Design Studio are now displayed on the touchscreen

If you use the integrated CAD / CAM workflow with TRIOS Design Studio, the patient name that you enter in the CAD application will now also be displayed on the touchscreen of the Z4.

DentalCNC

Error codes are now directly linked to our interactive troubleshooting guides

When DentalCNC displays an error code, the application now adds a link to the corresponding interactive troubleshooting guide if available.

DentalCNC will now automatically remove tools in case of a breakage

Does not apply to the Z4.

If a tool breakage is detected, DentalCNC will now remove the affected tools from the virtual ATB and virtual tool magazine. Therefore, you need to re-add them when exchanging the physical tools.

You can now activate and deactivate the ionizer for all corresponding machines

The Ionizer activated setting is now available for the following machines:

-

K5+

-

R5

-

S5

(R5) The automatic cleaning of the working chamber has been improved

To allow users to save time and give them more control over the process, we have optimized the automatic cleaning of the working chamber (DirectClean Technology).

Bug Fixes

DentalCAM

Image no longer overlaps with data in Excel report

In Excel reports for jobs with 10 or more objects, the image overlapped with parts of the data.

This behavior has been corrected.