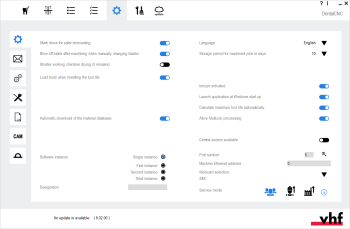

General application settings of dentalcnc

Where are the general settings of dentalcnc? How do I establish a connection to the machine?

The general application settings of dentalcnc contain miscellaneous settings which allow you to use dentalcnc in accordance with your working environment.

- Open the dentalcncApplication settings with the following icon in the main toolbar:

- Open the General settings with the following icon on the local toolbar:

Like other features in dentalcnc, settings are machine-specific. If a specific setting doesn’t display, it is not available for your machine.

The following settings are available:

If you want to use a disc again to manufacture additional objects from it, it is important to re-mount the disc in the same position.

To make this easier for you, the machine can mark the disc with 1 or 2 small holes. When you re-mount the disc, make sure that the holes are in the same position as when you removed the disc.

Some machines have a corresponding marking on their blank holder. If you use such a machine, you can align the marking on the disc with the marking on the blank holder. See your machine’s operating instructions.

- If you want the machine to mark discs, activate the Mark discs for safer remounting option.

- If you want the machine to remove the coarse dust from the blank after machining using compressed air, activate the Blow off blank after machining when manually changing blanks option.

- After machining, the spindle moves above the blank and blows it off with the air nozzles.

When using the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead, the machine will always blow off the blanks before they are automatically unloaded into the blank magazine

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead, the machine will always blow off the blanks before they are automatically unloaded into the blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading.. This setting has an effect only under the following conditions:

Part of the blank changer in which you store the blanks for automatic loading.. This setting has an effect only under the following conditions:

-

If you operate a machine with a blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead which allows you to mount blanks directly to the blank holder.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead which allows you to mount blanks directly to the blank holder. -

If you operate a machine without a blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead.

The automatic drying of the working chamber is part of the directclean technology of R5 machines.

By default, the process takes 15 minutes. If you want to manually dry the working chamber, you can reduce the duration to 2 minutes.

-

To reduce the duration of the drying process to 2 minutes, activate the Shorter working chamber drying (2 minutes) option.

Details on the directclean technology for R5 machines: See ‘directclean technology’.

If an integration of dentalcam & dentalcnc with a CAD application is available for your machine, you can activate the integration with this option.

-

To use the integrated workflow, select the option. In addition, please note Setting up CAD/CAM integration.

The material database is automatically updated by and updated via the Internet.

-

To turn off the automatic update, deactivate the Automatic download of the material database option in the general application settings of dentalcam and dentalcnc.

If you use the Multi-machine control function, you can use the control elements in the Software instance area to configure the individual software copies (instances).

-

To configure the individual instances, follow the corresponding instructions for the multi-machine control feature.

-

To deactivate the configuration of a specific instance, activate the Single connection option for the corresponding installation.

If this setting is activated, the machine will measure blocks before machining to ensure that a block with the correct dimensions is mounted in the blank holder. For this, the machine touches the blocks with a tool from 3 sides. If the measuring values differ from the expected values, you will be prompted accordingly.

We highly recommend activating this option.

-

To use the automatic block measurement function, activate the option.

- From the Language drop-down list, select the desired user interface language. Restart dentalcnc.

Jobs are removed from the Job list after they have been machined, but their data is not immediately removed from the CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc.. This enables you to restore machined jobs via the job archive so that they display in the job list again.

The computer that is connected to your machine and which runs dentalcam and dentalcnc.. This enables you to restore machined jobs via the job archive so that they display in the job list again.

As job data take up a significant amount of disc space, dentalcnc automatically removes the data after a specific time period. You can specify this time period in the general application settings of dentalcnc.

- From the Storage period for machined jobs in days drop-down list, select the number of days after which dentalcnc should delete the job data from the CAM computer

The computer that is connected to your machine and which runs dentalcam and dentalcnc..

The computer that is connected to your machine and which runs dentalcam and dentalcnc.. - After the selected number of days, dentalcnc automatically deletes data of machined jobs from the CAM computer

The computer that is connected to your machine and which runs dentalcam and dentalcnc.. The corresponding jobs still display in the job archive, but you can no longer restore them.

The computer that is connected to your machine and which runs dentalcam and dentalcnc.. The corresponding jobs still display in the job archive, but you can no longer restore them.

You can activate and deactivate the ionizer for certain machine models. If this option doesn’t show for your machine although it is equipped with an ionizer, the option is always activated.

-

If this option is deactivated, the ionizer won’t be used for any job.

-

If this option is activated, the ionizer will be used for selected jobs.

-

To activate the ionizer, activate the option.

If you activate this option, dentalcnc will automatically launch every time you (re-)start your CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc.. If you use the Z4, you need to activate this option for the automatic connection process to work.

The computer that is connected to your machine and which runs dentalcam and dentalcnc.. If you use the Z4, you need to activate this option for the automatic connection process to work.

If you use a different machine, you may want to activate this option if it is more convenient for you.

Keeping track of tool life values is one of the main functions of .

The formula is:

Maximum tool life — Operating time = Remaining tool life

You can manually enter the maximum tool life for each tool type in the Tool list in the dentalcnc settings.

In addition, dentalcnc can calculate the maximum tool life based on the maximum tool life values which have been achieved in the past.

- If you want dentalcnc to calculate the maximum tool life for each tool type, activate the Calculate maximum tool life automatically option.

- Every time you reset the tool life of a tool, dentalcnc uses the operating time that was actually achieved with the tool to re-calculate the maximum tool life of the corresponding type. The application updates the tool list accordingly.

You can manually overwrite tool life values which dentalcnc calculated, but as long as the Calculate maximum tool life automatically option is activated, the application will overwrite the manually adjusted values every time you reset the corresponding tool life.

The MultiJob function allows you to machine multiple jobs with the same ID using only 1 blank.

- To activate the Multijob function, activate the Allow MultiJob processing option.

By default, the vacuum sensor of machines which require an external air extraction system is calibrated when you open the working chamber door. If the suction unit is switched on during this calibration, the calibration will yield incorrect values. This will lead to incorrect vacuum monitoring.

Central extraction systems cannot be controlled by the machine or the user. If your machine is connected to such a system, you must deactivate vacuum sensor calibration.

- To deactivate vacuum sensor calibration, activate the Central suction available option.

- To calibrate the vacuum sensor:

- Disconnect the central extraction system from the machine.

- Deactivate the option.

- Open the working chamber door.

In order to control your machine, dentalcnc needs to know the correct USB port number. If you use the CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc. with only 1 machine, finding the port number is usually only required once upon installation of the machine and manufacturing software

The computer that is connected to your machine and which runs dentalcam and dentalcnc. with only 1 machine, finding the port number is usually only required once upon installation of the machine and manufacturing software![]() Term for the software package consisting of dentalcam and dentalcnc..

Term for the software package consisting of dentalcam and dentalcnc..

If you want to control multiple machines with 1 CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc., use our multi-machine control feature.

The computer that is connected to your machine and which runs dentalcam and dentalcnc., use our multi-machine control feature.

In most cases, dentalcnc can automatically determine the port number without manual configuration.

Establishing the connection between dentalcnc and your machine

-

To establish a connection to the following machine models, enter the machine network identifier in the Machine network identifier input field:

-

N4+

-

K5+

-

R5

How to determine the machine network identifier

-

Connect the machine directly to the CAM computer

The computer that is connected to your machine and which runs dentalcam and dentalcnc. with an Ethernet cable.

The computer that is connected to your machine and which runs dentalcam and dentalcnc. with an Ethernet cable. - Start dentalcnc.

- Switch on the machine at the main power switch.

-

Open SX Virtual Link.

Opening SX Virtual Link

-

In the SX Virtual Link application window, search for the machine network identifier. It displays at the beginning of the line.