Mounting and removing blanks

The workflow for restoration is as follows:

→

→

→

→

NOTICE

Damage to tools and blanks as well as defective machining results due to incorrect fixation

If blanks move or vibrate during machining, the result may become unusable. Tightening screws too much can damage blanks.

-

Tighten the screws on the clamping devices with the specified torque.

Suitable blanks

The machine can process the following blanks:

- Discs with a diameter of 98.5 mm – 98.8 mm

- Blocks, max. size: 45 x 20 x 20 mm (L/D/H)

- Prefabricated abutments*

Extra equipment![]() Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

How to mount the different blank types

| Blank type | Holder required? | Mount like this |

|---|---|---|

|

|

No |

Discs >> Blank holder or Discs >> Blank magazine |

|

Ivoclar Ivotion discs |

Ivotion mounting aids* |

Ivotion discs >> Blank magazine |

|

Calibration blanks |

No |

Calibration blanks >> Blank holder |

|

Blocks |

Yes |

Blocks

Blocks >> Block holder >> Blank magazine |

|

Prefabricated abutments |

Yes |

Prefabricated abutments >> Prefabricated abutment holders >> Blank holder or Prefabricated abutments >> Prefabricated abutment holders >> Blank magazine |

* The Ivotion mounting aids are available from customer service.

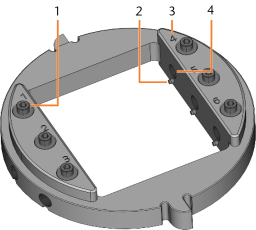

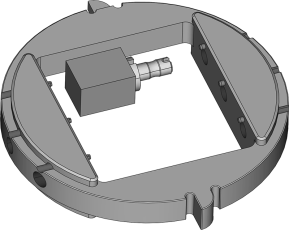

Mounting blocks to the block holder

You can clamp up to 6blocks in the block holder.

-

CAUTION!Wear gloves.

-

The block type, the number of blocks and the block positions must correspond to the corresponding job in DentalCAM.

-

Loosen the fixing screw at the desired position with the torque screwdriver supplied.

-

If the block is multilayered, align the blank so that the top layer of color is on top.

-

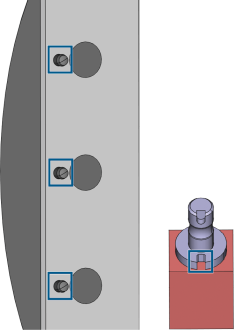

Position the block so that the positioning pin at the block holder (markings on the left) lies in the groove in the block shaft (marking on the right).

-

Insert the shaft of the block into the desired position in the block holder until it is firmly seated.

-

Use the torque screwdriver supplied to fix the block with the corresponding fixing screw. Tighten the screw firmly.

NOTICE! Tool breakages and defective machining results due to incorrect block assignment

Using an optional abutment holder

With an optional abutment holder, your machine can process prefabricated abutments with prefabricated connection geometries.

Abutment holders for common abutment systems can be obtained from customer service.

Supported prefabricated abutment blanks in DentalCAM 8

Supported prefabricated abutment blanks in DentalCAM 7

What's next?

If you want to mount blanks in the working chamber:

Mounting discs and block holders in the working chamber

If you want to mount blanks into the blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading.:

Part of the blank changer in which you store the blanks for automatic loading.: