Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

-

Have ready:

-

Close dentalcnc.

-

Open the working chamber door.

-

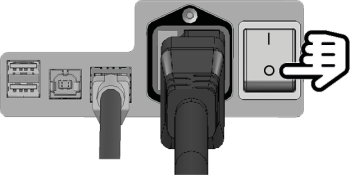

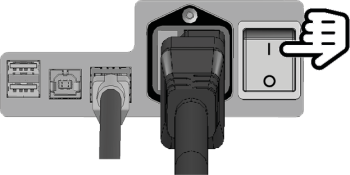

Switch off the machine at the main power switch.

-

CAUTION!Wear gloves.

-

NOTICE! Remove all tools from the tool magazine and remove the AirTool from the insert E1.

-

Disconnect the A-axis cable of the A-B axis module from the cable socket:

-

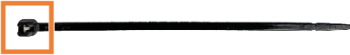

Carefully cut the cable tie at the cut line (marked green) with the side cutter. Do not damage the A-axis cable in the process.

-

Pull the A-axis cable downwards out of the cable socket.

-

Remove the cable tie.

NOTICE! Damage to the A-axis cable if you apply the side cutter too deeply.

-

-

Disconnect the A-axis cable of the A-B axis module:

-

Open the knurled nut at the left on the underside of the A-B axis module.

-

Pull the cable off downwards at the plug.

-

-

Remove the blank from the blank holder if present.

-

Pull the 4 cover caps (marked orange) off the 4 fixing screws on the A-B axis module.

-

Unscrew the 4 fixing screws of the A-B axis module with the angle screwdriver. Remove the fixing screws and washers.

-

Grasp the A-B axis module with both hands and pull it forwards off the driveshaft. Remove the A-B axis module from the working chamber.

-

Remove the blank holder from the removed A-B axis module. Attach the blank holder to the spare A-B axis module.

Please use the following instructions: Exchanging the blank holder.

-

Using both hands, slide the spare A-B axis module onto the driveshaft.

-

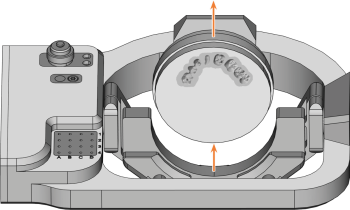

Insert the positioning pin on the A-B axis module (4) into the opening in the driveshaft (2).

-

Insert the positioning pin on the driveshaft (1) into the opening in the A-B axis module (3).

-

-

Positioning pin on the driveshaft

-

Opening in the driveshaft

-

Opening in the A-B axis module

-

Positioning pin on the A-B axis module

-

Use the torque screwdriver (5.0 Nm with TX25 bit). Tighten the A-B axis module crosswise with the 4 washers (marked orange) and the 4 fixing screws.

-

Attach the 4 cover caps to the 4 fixing screws of the A-B axis module.

-

Connect the A-axis cable to the connector at the left side of the underside of the A-B axis module:

-

Plug in the connector of the cable.

-

Screw the connector tight with the knurled nut.

-

-

Fasten the A-axis cable to the cable socket (marked green) with the cable tie:

-

Insert the cable tie into the cable socket from below. Bend it around the brackets of the cable base.

-

Press the A-axis cable into the cable base and hold it in this position.

-

Insert the end of the cable tie without the eyelet into the eyelet on the cable tie. Tighten the cable tie.

-

Cut off the protruding part of the cable tie with the side cutter.

-

-

Close the working chamber door.

-

Switch on the machine at the main power switch.

-

Start dentalcnc.

-

Calibrate the machine with manual tool change:

-

In the Machine data view in dentalcnc, turn on the manual tool change for the T17 position.

-

Assign the calibration tool to the AirTool insert E1 in the tool management view.

-

Calibrate the machine with dentalcnc. When prompted, manually insert the calibration tool into the collet chuck.

-

Measure the measuring sensor with dentalcnc.

-

Drill tool positions into the tool magazine inserts.

Drilling tool positions (holes) into new tool magazine inserts

-

Calibrate the machine with automatic tool change:

-

In the Machine data view in dentalcnc, turn on the manual tool change for the T17 position.

-

Insert the calibration tool into AirTool insert E1.

-

Calibrate the machine with dentalcnc.

-

Use a test specimen to check the mechanical accuracy of the machine.

-

If the test specimen is out of tolerance, contact Customer Service.

- Open the Maintenance section with the following icon in the main toolbar:

-

Select the icon shown for the Exchange tool magazine inserts entry.

Select the icon shown for the Exchange tool magazine inserts entry.