Exchanging the blank holder

You can remove and install the blank holder and the clamping devices on the blank holder independently of each other.

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

- Have ready:

-

Close the working chamber door.

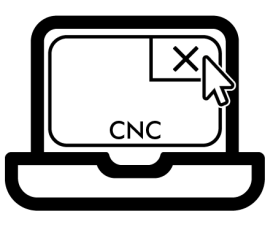

Move the axes into the default position by selecting the depicted icon in the Machining view in dentalcnc.

Move the axes into the default position by selecting the depicted icon in the Machining view in dentalcnc.- Exit dentalcnc.

-

Open the working chamber door.

-

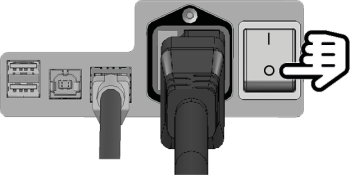

Switch off the machine at the main power switch.

-

CAUTION!Wear gloves.

-

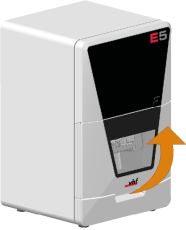

Gently turn the blank holder 180° upwards.

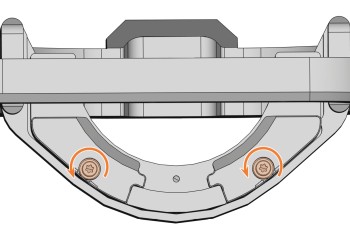

- If the 2 screws on the back of the blank holder are covered with caps (marked orange):

-

Pierce the cover caps with the pointed tool.

-

Pry out the cover caps.

-

Unscrew the 2 screws on the back of the blank holder.

-

Hold the blank holder. Gently turn the blank holder 180° down.

-

Pull the blank holder forward from the positioning pin and remove it upward from the working chamber.

-

A drill hole for the positioning pin is located on the rear side of the blank holder.

Slide the spare blank holder onto the positioning pin.

-

Hold the blank holder. Gently turn the blank holder 180° upwards.

-

- Screw the 2 screws into the back of the blank holder without tightening them.

-

Press the blank holder to the right and hold it in this position.

-

Tighten the right screw.

-

Tighten the left screw.

-

Gently turn the blank holder 180° down.

-

Check if the blank holder on the right side touches the contact surfaces of the blank holder support.

-

If this is not the case, realign the blank holder:

-

Gently turn the blank holder 180°.

-

Loosen the 2 screws without unscrewing them.

-

Continue with step 14 and follow the further steps.

-

-

Gently turn the blank holder 180° upwards.

-

Leave the 2 screws on the back of the blank holder uncovered.

-

Close the working chamber door.

-

Switch on the machine at the main power switch.

-

Start dentalcnc.

-

Calibrate the machine with dentalcnc.

NOTICE! Damage to tools, blanks and the machine if the blank holder is positioned incorrectly

Removing and installing clamping devices

You can unscrew the clamping devices, e.g., for cleaning purposes.

-

Have ready:

Removing the clamping device

-

Close the working chamber door.

Move the axes into the default position by selecting the depicted icon in the Machining view in dentalcnc.

Move the axes into the default position by selecting the depicted icon in the Machining view in dentalcnc.-

Open the working chamber door.

-

CAUTION!Wear gloves.

-

Remove the blank from the blank holder if present.

-

Unscrew and remove the 2 fixing screws from the 2 clamping devices.

-

Remove the 2 clamping devices.

Installing the clamping devices

-

CAUTION!Wear gloves.

-

Position the 2 clamping devices on the blank holder. The screw holes in the holder and in the clamping devices shall be superimposed.

-

Insert the 2 fixing screws into the screw holes.

-

Use the torque screwdriver (1.5 Nm) and screw down the 2 clamping devices with the 2 fixing screws.