Mounting and removing blanks

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

The workflow for restoration is as follows:

→

→

→

NOTICE

Damage to tools and blanks as well as defective machining results due to incorrect fixing

If blanks move or vibrate during machining, the result may become unusable. Tightening screws too much can damage blanks.

-

Tighten the screws on the clamping devices with the specified torque.

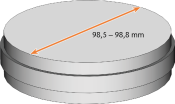

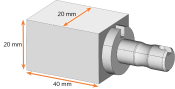

Suitable blanks

The machine can process the following blanks:

Extra equipment![]() Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

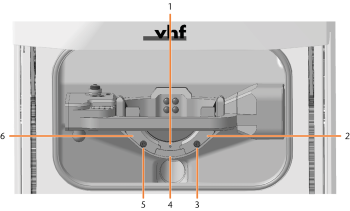

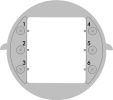

Overview of blank holders and standard clamping devices

-

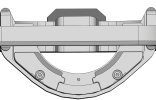

Marking for the safe remounting of discs

-

Right-hand clamping device

-

Fixing screw for right-hand clamping device

-

Blank holder

-

Fixing screw for left-hand clamping device

-

Left-hand clamping device

How to mount the different blank types

What's next?

If you want to mount discs:

Mounting discs in the working chamber

If you want to mount blocks: