Mounting discs in the working chamber

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

The workflow for restoration is as follows:

→

→

→

-

CAUTION!Wear gloves.

-

Open the working chamber door.

-

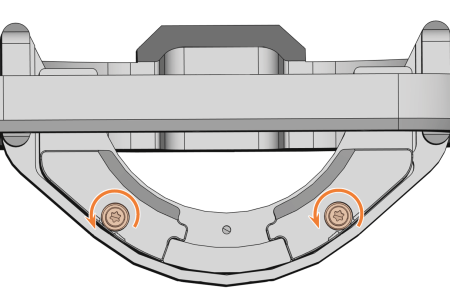

Loosen the 2 fixing screws on the blank holder without unscrewing them.

-

Remove the blank from the blank holder if present.

-

Use the disc as follows:

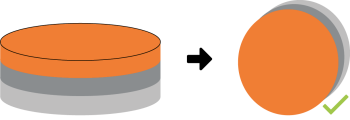

- If the disc is multilayered, align the blank so that the top layer of color points to you.

- If the disc was already machined, ensure that:

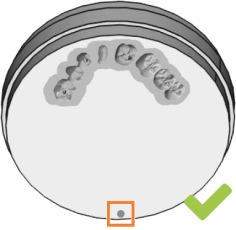

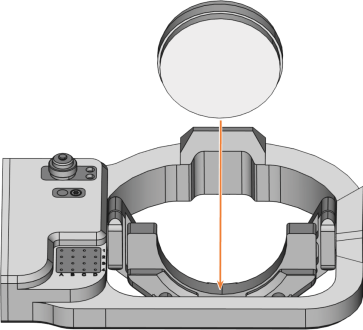

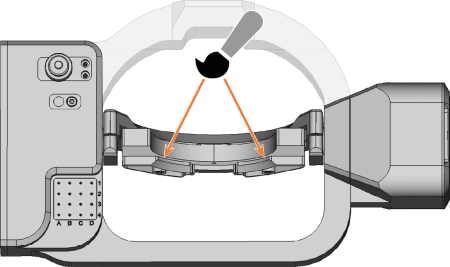

- If the disc has been marked for safer remounting via dentalcnc, make sure that the marking is in the position shown below.

-

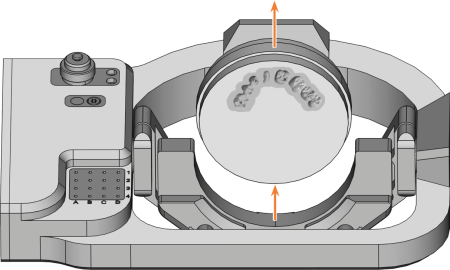

Insert the disc from above into the holder.

-

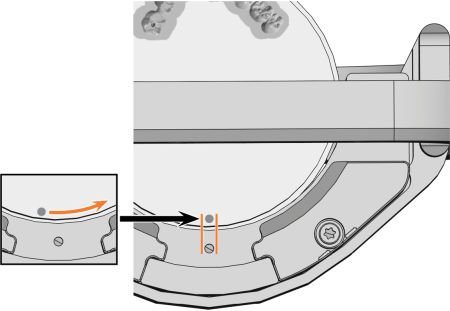

Carefully rotate blanks that have already been machined so that the marking on the blank is exactly above the marking on the blank holder.

- Remove machining residue from the back of the clamping elements with a brush. Do not use compressed air!

-

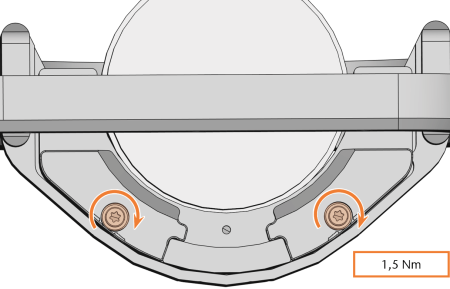

Tighten the fixing screws (marked orange) with the supplied torque screwdriver (1.5 Nm) as follows:

-

Screw in the left screw without triggering the torque limitation.

-

Screw in the right screw without triggering the torque limitation.

-

Tighten the left screw.

-

Tighten the right screw.

-

NOTICE! Blank damage due to machining residue and incorrect fixing in place

| Torque |

|---|

|

1.5 Nm For a less stable material such as zirconia, you can use a lower torque. |

Removing discs

-

CAUTION!Wear gloves.

-

Open the working chamber door.

-

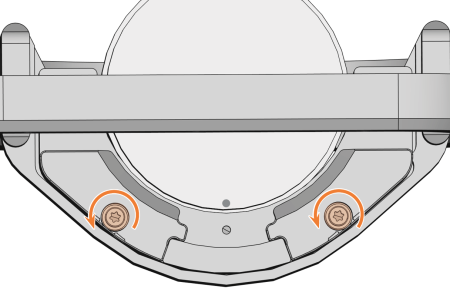

Loosen the 2 fixing screws without removing them.

-

Remove the disc from the blank holder.