Applies to: dentalcam & dentalcnc 8.11

Error code -2 – Tool breakage

dentalcnc aborts the job and displays the error code.

Interactive troubleshooting guide

Is at least 1 tool broken or damaged?

Do you use the latest dentalcam & dentalcnc version that is available for your machine?

Did you use the correct tools for the job?

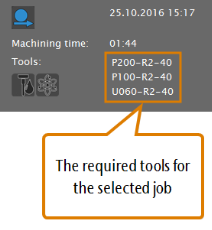

You can use the following information in dentalcnc to determine which tools are required:

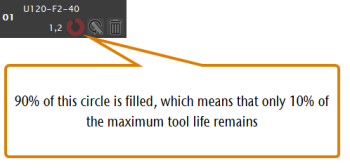

Was the remaining tool life sufficient for the job?

The tools must not be worn and the tool life must be sufficient for the whole job.

Did you mount the correct blanks for the job? Are the blank dimensions correct?

If you want to machine multiple blocks as part of 1 job, they must all be of the same material.

If the job was machined wet: Has cooling liquid been injected correctly into the working chamber?

Was the correct indication selected for each object?

The indications determine the machining strategies for the objects.

- Start dentalcam.

- If the job contains machined areas, restore the desired version of the blank.

- Edit the job.

- The Nesting view displays.

- In the left column, check the indications which are assigned to the objects. The indications are designated by letters.

Following you find a table showing the icons and the corresponding indications.

| Icon | Description |

|---|---|

|

|

Abutment |

|

|

Bite splint |

|

|

Denture |

|

|

Fully anatomical crown/bridge |

|

|

Crown/bridge (less detailed) |

|

|

Occlusal screw-retained bridge |

|

|

Implant bar |

|

|

Inlay/Onlay |

|

|

Partial frame |

|

|

Model plate |

|

|

Model plug-in tooth |

|

|

Secondary crown |

|

|

Surgical guide |

|

|

Telescope crown |

|

|

TempShell |

|

|

Veneer |

Recommendation

- Contact customer service.

Recommendation

- Check for a update and install it.

- If a firmware update is available for your machine, ensure that it is installed during or after the dentalcam update. Updating the firmware of the machine

- Restart the job.

Recommendation

- Exchange all broken and damaged tools.

- Exchange all incorrect tools.

- Restart the job.

Recommendation

- Exchange all broken and damaged tools.

- Exchange all worn tools.

- Restart the job.

Recommendation

- Exchange all broken and damaged tools.

- Exchange all worn tools.

- Restart the job.

Recommendation

- Mount a blank made of the correct material and with the correct dimensions.

- If the job was created with the wrong material / dimensions:

- Recreate the job in dentalcam.

- Calculate it.

- Exchange all broken and damaged tools.

- Exchange all incorrect tools.

- If you recreated the job in dentalcam, execute the new job.

- If you are using the original job, restart the job.

Recommendation

- Use the following guide to solve the cooling liquid issue:

- Exchange all broken and damaged tools.

- Restart the job.

Error code -8 – Flow rate too low

Recommendation

- Exchange all broken and damaged tools.

- If at least 1 object was assigned an incorrect indication, do as follows:

- Delete all objects with incorrect indications.

- Import and nest the objects again.

- Calculate the job.

- Execute the new job.

Recommendation

- Exchange all broken and damaged tools.

- Restart the job.