Applies to: dentalcam & dentalcnc 8.11

Error code -8 – Flow rate too low

dentalcnc aborts the job and displays the error code.

Interactive troubleshooting guide

Was cooling liquid injected into the working chamber at all?

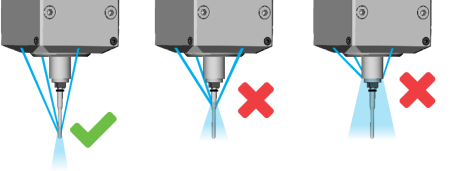

Is the spray pattern regular?

The pressure must be consistent and all jets must hit the tool tip.

Is the cooling liquid tank properly installed?

N4+, R5, Z4: The tank is in the drawer or compartment. The drawer or compartment flap is closed.

E4: The cooling liquid tank is inserted.

N4: The drawer is closed.

Wet grinding module NO-1: The module is connected to the machine and the module insert is installed.

Is there sufficient cooling liquid in the tank?

Did you clean the filter in the cooling liquid tank according to the maintenance table?

Machines with carbon filter: Are there activated carbon pellets in the carbon filter? Did you exchange the pellets according to the maintenance table?

Machines with cooling liquid coupling: Can the cooling liquid tank be easily attached to the coupling?

Does cooling liquid leak from the coupling?

Recommendation

- Contact customer service.

Recommendation

- Clean the tank and fill it with cooling liquid.

- Insert the tank into the machine.

- Restart the job.

Recommendation

For further details, refer to the machine’s operating instructions.

- Clean the tank and fill it with cooling liquid.

- Insert the tank into the machine.

- Restart the job.

Recommendation

For further details, refer to the machine’s operating instructions.

- Clean the filter.

- Clean the tank and fill it with cooling liquid.

- Insert the tank into the machine.

- Restart the job.

Recommendation

For further details, refer to the machine’s operating instructions.

- Clean the filter.

- Fill new activated carbon pellets into the carbon filter.

- Clean the tank and fill it with cooling liquid.

- Insert the tank into the machine.

- Restart the job.

Recommendation

For further details, refer to the machine’s operating instructions.

- Clean the coupling.

- Remove and reinstall the coupling as when exchanging it.

- Clean the tank and fill it with cooling liquid.

- Insert the tank into the machine.

- Restart the job.

- If the problem persists, exchange the cooling liquid coupling.

Recommendation

- Clean the coupling.

- Remove and reinstall the coupling as when exchanging it.

- Clean the tank and fill it with cooling liquid.

- Insert the tank into the machine.

- Restart the job.

- If the problem persists, exchange the cooling liquid coupling.

For further details, refer to the machine’s operating instructions.

Recommendation

- Contact customer service.

Recommendation

- Contact customer service.