Applies to: dentalcam & dentalcnc 8.12

Error code 34 or 60 – Spindle motor error / Stop by over current of the spindle

dentalcnc aborts the job and displays the error code.

There is an extended version of this troubleshooting guide available for vhf certified service employees:

Only E4 machines: Is there enough cooling liquid in the tank?

How to check this:

-

See the following E4 Help Article: Filling the cooling liquid

When did dentalcnc display the error code?

Does the spindle rotate when you start a job without any blank?

How to check this:

- Restart the machine.

- Execute a job without a blank in the working chamber.

- Check if the spindle is rotating as expected.

Does the spindle also rotate when you start a regular job?

How to check this:

- Mount a blank in the blank holder.

- Execute a suitable job. Use the correct tools.

- Check if the spindle is rotating as expected.

Can you rotate the spindle evenly by hand?

How to check this:

- Grab the collet chuck of the spindle with your thumb and index finger.

- Carefully rotate the collet chuck.

Did the tool/spindle collide with any object?

Can you rotate the spindle evenly by hand?

How to check this:

- Grab the collet chuck of the spindle with your thumb and index finger.

- Carefully rotate the collet chuck.

Did you use the correct tools for the job? Did you mount the correct blanks for the job? Are the blank dimensions correct?

If you want to machine multiple blocks as part of 1 job, they must all be of the same material.

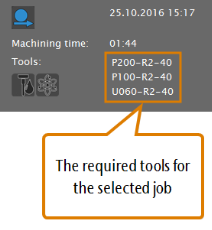

You can use the following information in dentalcnc to determine which tools are required:

Has the tool been pulled out of the collet chuck?

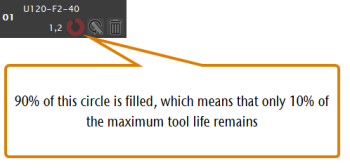

Was the remaining tool life sufficient for the job?

The tools must not be worn and the tool life must be sufficient for the whole job.

Was the correct indication selected for each object?

The indications determine the machining strategies for the objects.

How to check this:

- Start dentalcam.

- If the job contains machined areas, restore the desired version of the blank.

- Edit the job.

- The Nesting view displays.

- In the left column, check the indications which are assigned to the objects. The indications are designated by letters.

Following you find a table showing the icons and the corresponding indications.

| Icon | Description |

|---|---|

|

|

Abutment |

|

|

Bite splint |

|

|

Denture |

|

|

Fully anatomical crown/bridge |

|

|

Crown/bridge (less detailed) |

|

|

Occlusal screw-retained bridge |

|

|

Implant bar |

|

|

Inlay/Onlay |

|

|

Partial frame |

|

|

Model plate |

|

|

Model plug-in tooth |

|

|

Secondary crown |

|

|

Surgical guide |

|

|

Telescope crown |

|

|

TempShell |

|

|

Veneer |

Are there any nesting errors?

How to check this:

- Start dentalcam.

- If the job contains machined areas, restore the desired version of the blank.

- Edit the job.

- The Nesting view displays.

- Check for incorrectly marked drilling ranges and cavities. Visually inspecting drillings and cavities

- Check if there are any nesting errors.

Information on proper nesting:

Did vibrations occur during processing which were caused by incorrectly positioned bars?

How to check this:

- Start dentalcam.

- If the job contains machined areas, restore the desired version of the blank.

- Edit the job.

- The Nesting view displays.

- Check if all bars are correctly positioned.

Information on proper nesting:

Recommendation

-

Fill cooling liquid into the cooling liquid tank of your E4: Filling the cooling liquid

Recommendation

- Contact customer service.

Recommendation

- Contact customer service.

Recommendation

- Contact customer service.

Recommendation

The spindle bearings may be worn. The spindle may need to be replaced.

- Contact customer service.

Recommendation

- Mount a blank made of the correct material and with the correct dimensions.

- If the job was created with the wrong material / dimensions:

- Recreate the job in dentalcam.

- Calculate it.

- Exchange all incorrect tools.

- If you recreated the job in dentalcam, execute the new job.

- If you are using the original job, restart the job.

Recommendation

-

Clean the collet chuck as described in the machine’s operating instructions.

- If the collet chuck is defective or too soiled to be properly cleaned, exchange it for a spare collet chuck.

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

Recommendation

- Exchange all worn tools.

Recommendation

- Exchange all broken and damaged tools.

- If at least 1 object was assigned an incorrect indication, do as follows:

- Delete all objects with incorrect indications.

- Import and nest the objects again.

- Calculate the job.

- Execute the new job.

Recommendation

- Delete bars for all incorrectly nested objects.

- Correct the position and orientation of the objects.

- Mark drilling ranges and cavities as required.

- Set bars for all objects.

- Calculate the job.

- Execute the new job with dentalcnc.

Information on proper nesting:

Recommendation

- Delete all incorrectly set bars.

- Correct the position and orientation of the objects.

- Set bars for all objects.

- Calculate the job.

- Execute the new job with dentalcnc.

Information on proper nesting:

Recommendation

At least 1 STL file may be incorrectly designed.

- Check if the STL files used in the job are correctly designed. Preparing STL files for good machining results

- If you find any design or export errors, do the following:

- Export all incorrect STL files with the correct settings / design.

- Open the job in dentalcam.

- If the job contains machined areas, restore the desired version of the blank.

- Edit the job.

- The Nesting view displays.

- Delete all defectively designed objects.

- Import and nest the objects again. Use the corrected STL files.

- Calculate the job.

- Execute the new job with dentalcnc.

- If you cannot find any incorrectly designed STL files, contact customers service.