New functions | Improvement of an existing function | Bug Fixes

P2

This is a maintenance update. It fixes an error that could occur during the initial installation of dentalcam & dentalcnc. Existing installations are not affected. Therefore, no update is offered in dentalcnc .

Error description: When loading STL files, dentalcam displayed an error message because the file VCMP120.DLL was missing. This was due to a missing redistributable package. This behavior has been corrected.

-

You can install the redistributable package manually from the dentalcam & dentalcnc setup folder:

…\Setup\Data\run\CAM\Data\run\mws\Redist\vcredist_2013_x64.exe

-

You can download the redistributable package from the Microsoft website: Click or tap here.

P1

This is a maintenance update.

-

E5: The machining of zirconia has been improved.

-

N4+, K5+, R5: The recording of machining via the webcam is now disabled by default. You can activate this again using the new option Record webcam in the general program settings of dentalcnc .

-

dentalcam 8.09 can now also be installed in parallel with the 32-bit version of Microsoft Office.

-

Firmware updates could lead to crashes. This behavior has been corrected.

Highlights

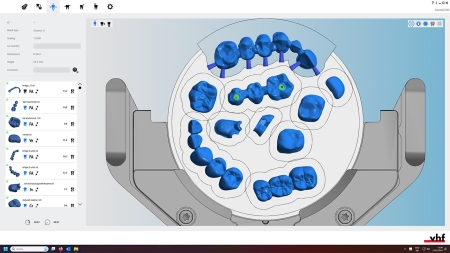

dentalcam

dentalcam now with full screen function

You can now display the program in full screen by clicking on the following icon in the top right-hand corner of the dentalcam window: ![]()

(E5) New machining function: Anterior tooth machining

The anterior tooth editing machining function can be used to reduce the amount of residual material caused by narrow interdental spaces or undercuts when machining selected tooth surfaces.

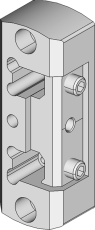

(N4+) New validated eMax machining strategy and block holder with PrograMill shank holder supported

As of this version, you can use the block holder with a PrograMill shank holder (extra equipment![]() Physical component which must be obtained separately and which adds new functionality to your machine.).

Physical component which must be obtained separately and which adds new functionality to your machine.).

Extra equipment![]() Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

Physical component which must be obtained separately and which adds new functionality to your machine. can be obtained from your customer service provider.

To process the e.max blocks clamped there with the new validated strategy, select the material IPS e.max validated -B.

Improved quality of cavities and basal surfaces for crowns and bridges with reduced detail

Optimizing the processing strategies increases the machining quality of cavities and basal surfaces of crowns and bridges with reduced detail.

Additional tools are used for this purpose:

-

Cavities: 0.6-mm milling cutter when activated

-

Basal surfaces: 1-mm milling cutter, and 0.6-mm milling cutter when activated

To activate optional tools, see Optional tools.

Additional features and changes

dentalcam

(N4+) All positions of the block holder can now be used for CAD/CAM integration with exocad ChairsideCAD

exocad has removed the restriction to the middle position of the block holder in exocad ChairsideCAD. Depending on the block type, you can now use additional positions of the block holder. To do this, you must update to the latest version of exocad ChairsideCAD.

Scrolling through lists with mouse wheel is now possible in all applications

You can now use the mouse wheel to scroll anywhere, e.g., through drop-down lists.

Hybrid ceramic blocks can now also be milled

Up to now, hybrid ceramic blocks have been ground. As of this version, blocks from this material group can be milled as an alternative.

-

Surfaces become smoother / shinier when milling than when grinding.

-

With some hybrid ceramics, the lower tool displacement can make it easier to set fits when grinding.

-

With the new option, you can adapt the machining type to your tool stock.

You do not select the desired machining type in the settings for blank types. Instead, there is now an additional entry in the material list for each affected blank type with the addition C-tool after the name.

Example:

-

Implemented before 8.09: Nacera Hybrid -B – Blank type with the machining type Grinding.

-

Implemented with 8.09: Nacera Hybrid C-tool -B: The same blank type with the machining type Milling.

|

Designation |

|---|

|

Coltene BRILLIANT Crios C-tool -B |

|

edelweiss C-tool -B |

|

HASS Amber Mill -H C-tool -B |

|

ITENA Numerys HC C-tool -B |

|

Nacera Hybrid C-tool -B |

|

Tetric C-tool -B |

|

Upcera Hyramic C-tool -B |

|

VOCO Gradio blocs C-tool -B |

Improved import of XML files for prefabricated abutment blanks

The XML files that dentalcam reads when importing prefabricated abutment blanks are now evaluated better. For example, file names with certain special characters such as umlauts are now possible.

Larger program window for chairsidecam

The program window size of chairsidecam is now identical to the program window size of dentalcam.

The following entry also applies to chairsidecam: dentalcam now with full screen function

Standard file selection window

From now on, dentalcam uses the standard Windows file selection window in all applications.

dentalcnc

(E4) Improved test and calibration specimen

Due to an adapted shape, test and calibration specimens can now be milled better.

The following tools are used for this purpose:

-

As before: P250-F1-40-T

-

Additionally: P200-R1-40

Faster import of NC files

The import of NC files when using a third-party CAM program is now faster.

Bug Fixes

dentalcam

Scroll bar in the blank archive is still displayed when the last blank is deleted

If the blank was deleted at the end of the list in the blank archive, dentalcam hid the scroll bar. As a result, the non-visible entries were no longer accessible.

This behavior has been corrected.

As a result, the order of the blanks in the blank archive is slightly changed once after the update. No blanks are removed.

dentalcnc

Preview images for third-party CAM software are displayed correctly

The preview images for blanks when using a third-party CAM program were not displayed correctly.

This behavior has been corrected.