Exchanging the spindle unit

Recommendation: If the replacement of the spindle and bellow is due in accordance with the Table of wear parts and spare parts, replace the two components at the same time.

In that case we recommend the following sequence:

-

Detach the bellow from the spindle unit.

-

Remove the spindle unit.

-

Remove the bellow.

-

Install the spare bellow and attach the spare bellow frame.

-

Install the spare spindle unit.

-

Attach the spare bellow in the working chamber.

Description steps 1, 3, 4, 6: Exchanging the bellow

Description steps 2, 5:

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

When exchanging the spindle, exchange the entire spindle unit, which consists of the following components:

-

Spindle including collet chuck

-

Collet chuck release unit including cable

The spindle unit is located behind the top service cover and the safety cover:

-

Have ready:

-

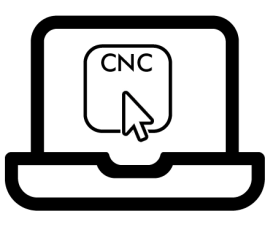

Start dentalcnc.

- Open the Maintenance section with the following icon in the main toolbar:

-

The spindle moves into the spindle exchange position.

-

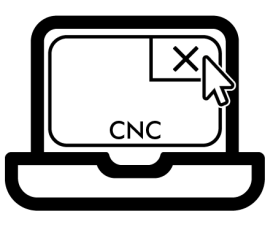

Close dentalcnc.

-

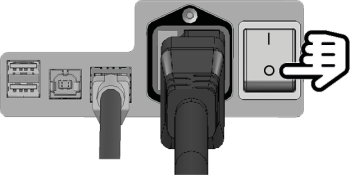

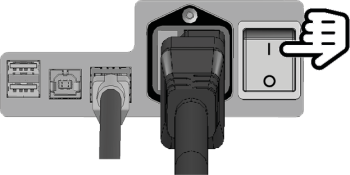

Switch off the machine at the main power switch.

-

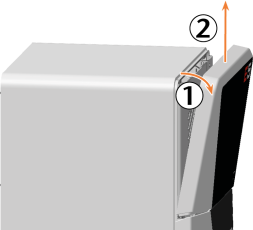

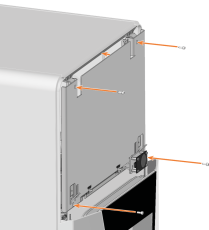

Remove the top service cover:

-

Grasp the recess on the left and right sides of the service cover.

-

Lift the service cover out of the tabs.

-

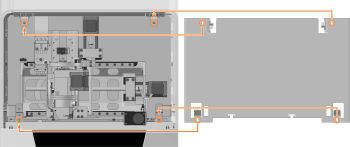

Use the 1.5 Nm torque screwdriver to unscrew the 4 screws that secure the safety cover.

-

Remove the safety cover.

- Loosen the spindle cable by manually turning the knurled nut anti-clockwise.

-

Unplug the spindle cable from the spindle connector.

-

Remove the collet chuck release unit cable:

Push both mounting clips on the connector toward the center and pull the connector out of the socket.

-

Loosen the fixing screw with the torque screwdriver. Do not unscrew the screw completely.

-

Remove the spindle by pulling it upward out of the spindle holder.

-

If the spindle cannot be pulled out, do the following:

-

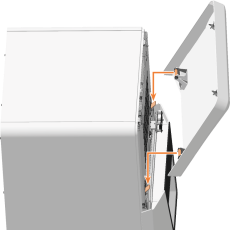

Open the working chamber door using the emergency release.

-

Loosen the screws securing the mounting washer to the bellow without unscrewing it.

-

Close the working chamber door.

-

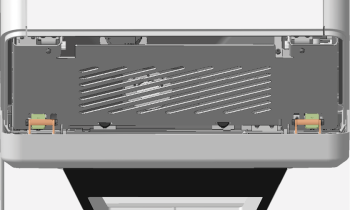

Pick up the spare spindle and locate the positioning pin hole (marked orange) on the bottom.

-

Rotate the spindle so that the positioning pin aperture (marked orange) is in the front left.

-

Insert the replacement spindle from above into the spindle holder:

-

Insert the positioning pin on the spindle bracket (marked in green) into the positioning pin opening (marked in orange) in the spindle.

-

Gently push the spindle down, paying attention to the spindle height indicator.

-

-

Once you have pushed the spindle down sufficiently, you will see the green ring on the spindle height indicator.

-

Tighten the screw to fix the spindle using the torque screwdriver.

-

Plug the spindle cable into the spindle connector.

-

Tighten the spindle cable by manually turning the knurled nut clockwise.

-

Insert the collet chuck release unit cable into the corresponding connector in the machine.

-

Position the safety cover so that the 4 screw holes are located above the 4 screw holes in the machine housing.

-

Secure the safety cover to the machine housing using the 1.5 Nm torque screwdriver.

-

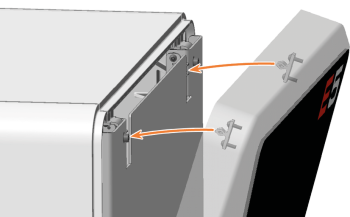

Attach the top service cover:

-

Insert the bolts (marked orange) of the service cover into the holders (marked green) on the safety cover.

-

Tilt the service cover towards the machine until it clicks into place.

-

-

Switch on the machine at the main power switch.

-

If you have loosened the screws securing the mounting washer to the bellow, do the following:

-

Open the working chamber door.

-

Tighten the screws.

-

Close the working chamber door.

-

Start dentalcnc.

- Open the Maintenance section with the following icon in the main toolbar:

-

Select the following icon of the entries Exchange spindle and Exchange spindle collet chuck:

-

Mill a test specimen and calibrate the machine as necessary.

-

Contact customer service and have the spindle operating hours reset.

This can be important for deciding warranty claims.