New functions | Improvement of an existing function | Bug Fixes

P2

- Measured values are output again during the axis power test, end switch test and measuring sensor test.

- When installing dentalcnc 8.11 P1, no desktop icons were created. This behavior has been corrected.

P1

-

The setup program

A separate program called "Setup.exe" which installs the applications on your hard drive. now enters dentalcam as an application for high-performance graphics units. This means that Windows uses the more powerful graphics unit on laptops with 2 graphics units of different performance. This has no effect on existing installations.

A separate program called "Setup.exe" which installs the applications on your hard drive. now enters dentalcam as an application for high-performance graphics units. This means that Windows uses the more powerful graphics unit on laptops with 2 graphics units of different performance. This has no effect on existing installations. -

It was not possible to mark cavities with a drilling. This behavior has been corrected.

New features and changes

dentalcam / chairsidecam

Program updates are now also possible via dentalcam

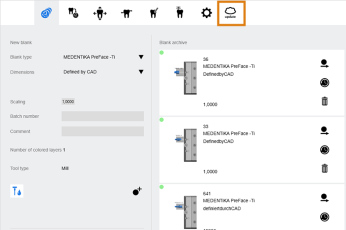

From now on, updates are now also available at dentalcam. As in dentalcnc, you can start updates with the following icon in the main icon bar:

This means you will never miss an update, even on computers on which you only use dentalcam.

-

This method does not automatically update the firmware.

-

This method is not available for Z4 machines.

For the new update instructions, see Updating dentalcam and dentalcnc.

Oversizes of fits for cavities can now also be defined for veneers

The option of defining oversizes of fits for cavities is now also available for veneers.

The function corresponds to the existing function for inlays and onlays. A description of these machining parameters can be found at Editing machining parameters and optional tools.

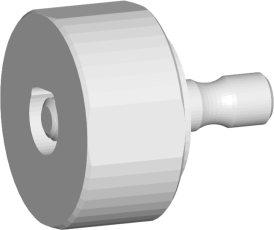

(Z4) Updated display for the DESS Pre-milled abutment holder

The display in the nesting view now corresponds to the current variant B of the DESS Pre-milled abutment holder. You can continue to use variant A.

For revised instructions on how to use the DESS Pre-milledabutment holder, see Installing and using the DESS Pre-milled abutment holder.

Bug Fixes

dentalcam & dentalcnc

Elimination of OEM restrictions for CAD/CAM integration

Materials that are not available for the installed OEM version of dentalcam & dentalcnc could not be calculated with the integrated CAD/CAM workflow.

This behavior has been corrected.

dentalcam / chairsidecam

Calculation errors have been fixed

Various calculation errors were possible in all kinds of materials.

This behavior has been corrected.

Tool collision during the machining of prefabricated abutment blanks eliminated

The M100 tool could collide with residual material and break.

This behavior has been corrected.

The residual material is now removed.

Unwanted surface structures near bars no longer occur

dentalcam could produce undesirable surface structures due to incorrectly calculated milling paths near bars.

This behavior has been corrected.

Reduced bars are properly machined again

Unnecessary residual material could remain when reducing bars.

This behavior has been corrected.

Milled labels on objects functions as intended again

The following behavior occurred:

-

Markings with a milling depth of -0.5 mm and below were not milled.

-

The position of labels was shifted.

This behavior has been corrected.

3Shape import: Alignment of ASC abutment blanks from DESS has been corrected

If you have imported objects from the 3shape Dental System or Trios Implant Studio, you sometimes had to manually correct the alignment in the nesting view.

This behavior has been corrected.

From now on, the alignment in dentalcam is always suitable for the abutment holder.

Calculation error for very small cavities eliminated

The calculation of the machining strategy for very small cavities could cause an error.

This behavior has been corrected.

(chairsidecam) Modified scaling factors are displayed correctly again

When changing the scaling factor, chairsidecam used the value for scaling the objects, but did not display it on the surface.

This behavior has been corrected.

Modified sinter bars with a milled-out inner body are displayed correctly again

If you changed the parameters of a sinter bar with a milled inner body, the original and modified geometry of the inner body were displayed simultaneously.

This behavior has been corrected.

The indication protrusion splint remains pre-assigned after a restarting dentalcam

Previously, the indication protrusion splint in the STL import view was reset to the entry Fully anatomical crown/bridge each time dentalcam was restarted.

This behavior has been corrected.

Setting for diamond-coated single-tooth cutter for composites is permanently saved again

The Use a diamond-coated single-tooth cutter setting was always deactivated when dentalcam was restarted.

This behavior has been corrected.

Program icons are displayed correctly in the taskbar again

The program icons were unintentionally grouped in the taskbar and displayed in incorrect colors.

This behavior has been corrected.

dentalcnc

(Z4) Machines shut down properly with a Remote Desktop Connection

With an active or terminated Remote Desktop Connection, it could happen that Windows on the CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc. was not closed properly when the machine was shut down. This affected machines with internal and external CAM computers

The computer that is connected to your machine and which runs dentalcam and dentalcnc. was not closed properly when the machine was shut down. This affected machines with internal and external CAM computers![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc..

The computer that is connected to your machine and which runs dentalcam and dentalcnc..

This behavior has been corrected.

(E3) Machining time now also shows values below 1 minute

The minimum machining time displayed was 1 minute.

This behavior has been corrected.

Changes in the maximum tool life now updates the correct tools in the virtual ATB

When changing the maximum tool life in the tool list, the changes for incorrect tools were adopted in the virtual ATB.

This behavior has been corrected.

Preview images of jobs are no longer transparent

If a blank view other than the top view was selected when starting the job calculation in dentalcam, the corresponding preview image in dentalcnc was displayed transparently.

This behavior has been corrected.

Known Issues

Restricted character selection for installation path for dentalcam installation

If you install dentalcam and dentalcnc, the following characters are not permitted in the installation path, in addition to the restrictions imposed by Windows:

( ) , ;

Please also note this restriction if you change the installation path later.

We plan to correct this behavior in a future release.