New functions | Improvement of an existing function | Bug Fixes

P3

This is a maintenance update.

-

Z4 machines with internal CAM computer

The computer that is connected to your machine and which runs dentalcam and dentalcnc.: An offline installer for the .NET framework is now available.

The computer that is connected to your machine and which runs dentalcam and dentalcnc.: An offline installer for the .NET framework is now available. -

Bug fix: chairsidecam no longer terminates prematurely.

-

Bug fix: A calculation error for STL files above the center line of the blank has been fixed.

Highlights

dentalcam

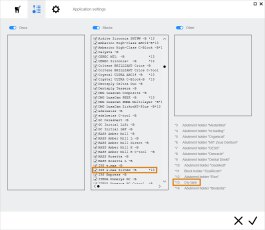

(K5, K5+, R5, E5) Validated strategy for Ivoclar Ivotion oversize process available

You can now create jobs for the Ivoclar Ivotion oversize process in dentalcam and mill them with a validated strategy on vhf dental machines.

This function complements the strategy already implemented for monolithic Ivotion discs.

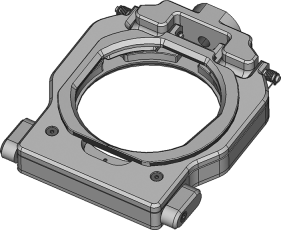

You need a specific Ivotion mounting aid for each machine type. Retrofit kits are available from customer service.

(N4, N4+, S1, S2, S5) Biodenta PreFAB-4 abutment holder is now supported

You can now activate and use the Biodenta PreFAB-4 abutment holder in dentalcam.

Additional features and changes

dentalcam & dentalcnc

Tool collisions due to incorrect calculations are now avoided

dentalcnc either cancels faulty jobs during machining or does not start them at all.

dentalcam / chairsidecam

Warning message for fully reduced bars only

If you have only used fully reduced bars in a job, dentalcam will now warn you before calculating the job.

dentalcnc

(E3, E4, E5) The multi-machine control has been improved

This improvement requires a new installation for technical reasons. After updating to version 8.10, only the old version of the multi-machine control is still available.

-

To receive the latest installation package, contact your customer service.

-

The E series is now supported.

-

The entries in dentalcnc for the 2nd and 3rd instance are now pre-assigned.

All details can be found in the revised instructions Setting up multi-machine control.

Bug Fixes

dentalcam & dentalcnc

dentalcam

The residual material display no longer shows any removed material for abutments

The residual material display for prefabricated abutments showed material that was removed during machining.

This behavior has been corrected.

Fully reduced bars between object and sinter bar are now correctly separated

Fully reduced bars between object and sinter bar were partially separated at the sintered bar instead of at the object.

This behavior has been corrected.

Pre-assigned height of sinter bars is now adjusted to the disc height if required

When creating a sinter bar, dentalcam adopts the height and width of the previously created sinter bar to simplify operation. This was also the case if the following disc was not sufficient for the bar height. If the value was not corrected manually, calculation errors caused tool breakage.

This behavior has been corrected. dentalcam Immediately adjusts the pre-assigned height of the sinter bar to the disc height.

Machining of drill holes in cobalt chrome has been improved

When machining cobalt chrome, a strategy correction has improved the accuracy of fit of drill holes.

Tool collisions eliminated

With different machining strategies and materials, the tool could collide with the disc.

This behavior has been corrected.

Drops in cavities are prevented

It could happen that dentalcam incorrectly positioned drops in cavities and calculated them accordingly.

This behavior has been corrected.

Improved error handling for attachments

If Matrix or Patrix were marked incorrectly for attachments, dentalcam displayed an incomprehensible error message or crashed.

This behavior has been corrected.

Vita CAD Temp multicolor can now be properly edited again

The following undesirable behavior occurred:

-

Instead of being placed on the blocks, objects were placed in the center of the blank display after import.

-

When nesting Vita CAD Temp multicolor blocks, the block holder was displayed with the wrong orientation. This led to tool breakages and a deviation between the nesting and machining position at R5 .

This behavior has been corrected. Selection and machining are now possible again.

Restoring jobs works as expected again

Errors could occur when restoring jobs.

This behavior has been corrected.

Objects can now be moved precisely even with a remote connection

If you were working with your CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc. via a remote connection, it was only possible to move objects in the nesting view step by step. This made precise positioning difficult.

The computer that is connected to your machine and which runs dentalcam and dentalcnc. via a remote connection, it was only possible to move objects in the nesting view step by step. This made precise positioning difficult.

This behavior has been corrected.

(E4, N4+, Z4) Residual material display for CAD/CAM integration with exocad ChairsideCAD has been corrected

For objects calculated with active CAD/CAM integration with exocad ChairsideCAD , the residual material display was incorrect.

This behavior has been corrected.

dentalcnc

(E3) Machining time now also shows values below 1 minute

The minimum machining time displayed was 1 minute.

This behavior has been corrected.

(Z4) Delayed display initialization fixed

The display is now initialized more quickly, which means the machine is ready sooner.

Unintentional starting of jobs is now prevented

After starting a job, the corresponding icon is immediately locked. This prevents unintentional multiple clicks that would automatically start the next job immediately afterwards.

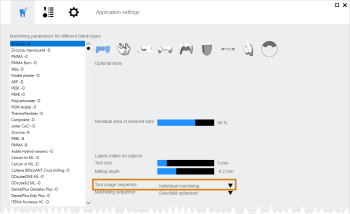

Manual cavity check: specification for oversize has been corrected

When checking cavities manually during machining, 0.010 mm was always specified as the value for the changed oversize, even if the actual oversize for the respective material deviated from this.

This behavior has been corrected.

Program remains in the foreground when restoring jobs

When restoring jobs in the job archive, dentalcnc was unintentionally moved to the background.

This behavior has been corrected.