Controlling the machine to prepare machining

How can I control the machine?

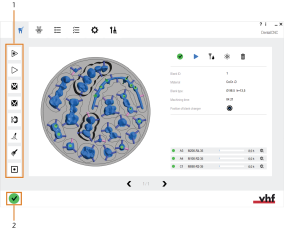

You can find the control elements for machine control in the Machining view.

- Open the Machining view with the following icon in the main toolbar:

You can find additional control elements for machines with a blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead in the Job list view.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead in the Job list view.

In addition, you can find a similar icon bar with additional options in the Current machine parameters view.

- Open the dentalcncApplication settings with the following icon in the main toolbar:

- Open the Current machine parameters view with the following toolbar icon:

The functions of the icons are as follows:

-

Icons which only display in the Machining view are marked with an orange line.

-

Icons which only display in the Current machine parameters view are marked with a gray line.

This function is used for the following:

-

Machining multiple jobs using the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead of your machine.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead of your machine. -

Machining multiple jobs with the same ID into 1 blank. This function does not require a blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead.

- If the working chamber door of your machine can open or close automatically, select the following icon to open or close it:

- The door opens or closes. The icon changes color to indicate the new state of the working chamber door.

When the axes of the machine are moving, the working chamber door will not open.

The axes of the machine do not move when the working chamber door is open.

While the axes are in the default position, you can carry out standard tasks such as:

- Mounting blanks into the blank holder

- Inserting or removing tools

Removing and cleaning the collet chuck is an essential part of machine maintenance. Sometimes, it may also be necessary to manually remove a tool from the collet chuck. In both cases, you need to open the collet chuck.

For complete instructions on how to clean the collet chuck, see the documentation for your machine.

- Close the working chamber door.

- Select the following icon:

- The following happens:

- The spindle moves to the tool change position.

- If your machine is equipped with an automatic working chamber door, the door automatically opens.

- h dentalcnc prompts you to confirm the opening of the collet chuck.

-

CAUTION!Wear gloves.

- Open the working chamber door.

- If there is a tool in the collet chuck of the spindle, hold it in place.

- Confirm the current message.

- The collet chuck opens.

- If present, remove the tool from the collet chuck.

- If desired, remove, clean and reinstall the collet chuck.

- If your machine is equipped with a manual working chamber door, close the door.

- To move the spindle back to the default position, select the following icon:

- The following happens:

- If your machine is equipped with an automatic working chamber door, the door automatically closes.

- The spindle moves to its default position.

- If your machine is equipped with a touchscreen, you can activate and deactivate it by selecting the following icon:

Deactivating the touchscreen is recommended if you operate the machine only with dentalcnc. Otherwise, you will still need to use the touchscreen for some actions.

Z4: To maintain the machine, only use the maintenance section on the touchscreen and not the one in dentalcnc.