Machining multiple jobs with the same ID in one blank

Can I machine multiple jobs with the same blank in 1 session?

In this section, we assume that you are already familiar with the standard machining workflow for your machine. If you need help with this, see the following Help Articles:

Imagine the following:

- You created a job in DentalCAM, but for one reason or another you nested fewer objects than possible in your blank.

- You calculated the job.

- Without manufacturing the job, you added additional objects to the blank and calculated it again.

- Maybe you did this several more times.

- You now have multiple jobs in the job list in DentalCNC for the same blank. As they are all based on the same original blank, they all have the same blank ID.

Example:

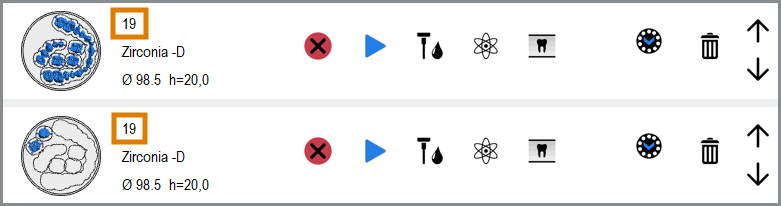

The following entries in the Job list have the identical blank ID (marked orange).

-

The job displayed in the first line was calculated first.

-

For the job displayed in the second line, 2 additional objects were added to the blank and the job was calculated a second time.

2 jobs in the Job list with an identical ID (marked orange)

Instead of starting both jobs individually, you can automatically process them in succession using the Multijob function.

Diagram: Multiple jobs (same ID), 1 blank

Machines without a blank changer

The following instructions do not apply to machines with a blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead even if you can directly mount a blank into the working chamber.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead even if you can directly mount a blank into the working chamber.

- Make sure that the MultiJob function is activated

- Follow the standard workflow for manufacturing a single blank without a blank changer. While doing so, select any of the corresponding jobs with the same ID (it doesn't matter which one).

- Instead of starting the manufacturing process with the standard icon, select the following icon:

- All jobs that have the same ID as the job which you selected will be machined.

Machines with a blank changer

For this function to work, you must load the blank from the blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading. even if you can directly mount a blank into the working chamber.

Part of the blank changer in which you store the blanks for automatic loading. even if you can directly mount a blank into the working chamber.

- Make sure that the MultiJob function is activated

- Follow the standard workflow for manufacturing multiple jobs using a blank changer. While doing so, assign all jobs with the same ID to the same blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slot.

Part of the blank changer in which you store the blanks for automatic loading. slot. - Mount the correct blank into the corresponding blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead slot of your machine.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead slot of your machine. - (Optional) Assign additional jobs to the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead. You can combine the Multijob function and standard jobs as required.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead. You can combine the Multijob function and standard jobs as required. - Start the manufacturing process as usual.

Assigning multiple jobs with the same ID to 1 blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading. slot

Part of the blank changer in which you store the blanks for automatic loading. slot

What's next?

While machining usually works fully automatically, there are some tasks which require your interference.