Applies to: DentalCAM & DentalCNC 8.11 / S2 / S5

Error code -1000 or -2000 – Error while unloading the blank

This error code can occur while the machine is unloading a blank from the working chamber into the blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading..

It indicates that the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage could not reach its end position to install the blank in the blank magazine

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage could not reach its end position to install the blank in the blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading..

The corresponding end switch or sensor did not send a signal.

Interactive troubleshooting guide

Did the blank in the blank carriage collide with a blank in the blank magazine?

How to check this:

- Open the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. door.

Part of the blank changer in which you store the blanks for automatic loading. door.

- Open the working chamber door.

- Check if the blank in the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage has collided with a blank in the blank magazine

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage has collided with a blank in the blank magazine Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading..

Is the blank magazine soiled?

Have you recently cleaned the release plate (S2) or the release bolts (S5)?

The S2 and S5 use different mechanisms to release the blank frames during loading and unloading.

- S2 1 x Release plate

- S5 4 x Release bolts

Does cleaning the release plate or release bolts solve the issue?

The S2 and S5 use different mechanisms to release the blank frames during loading and unloading.

- S2 1 x Release plate

- S5 4 x Release bolts

How to check this:

- Clean the release plate. S2: Cleaning the release plate of the blank changer

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

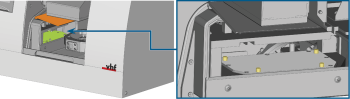

When reinserting the cover plate, do not forget to attach the washers.

- Close the working chamber door.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in DentalCNC.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in DentalCNC.- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap opens and the 4 bolts move upwards.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap opens and the 4 bolts move upwards. - Open the working chamber door.

- Clean the following components:

- Both sides of the blank changer

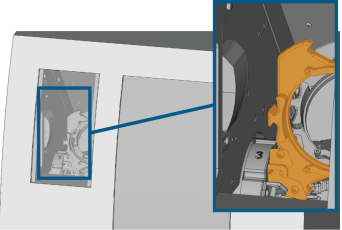

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) - The bottom surface between the working chamber and the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. (marked green)

Part of the blank changer in which you store the blanks for automatic loading. (marked green) - The 4 release bolts (marked yellow)

- Both sides of the blank changer

- Close the working chamber door.

- Confirm the message in DentalCNC.

- The release bolts move downwards and the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap closes.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap closes.  Move the axes into the default position by selecting the depicted icon in the Machining view in DentalCNC.

Move the axes into the default position by selecting the depicted icon in the Machining view in DentalCNC.- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly. - If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

The blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange), the bottom surface (marked green), the 4 release bolts (marked yellow)

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange), the bottom surface (marked green), the 4 release bolts (marked yellow)

Only S2: Did you reinstall the cover plate correctly after cleaning the release plate?

When reinstalling the cover plate, especially the washers are often forgotten.

How to check this:

- Remove and reinstall the cover plate according to the instructions. S2: Cleaning the release plate of the blank changer

Are the blank changer carriage and blank changer flap blocked?

How to check this:

- Open the working chamber door.

- Open the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. door.

Part of the blank changer in which you store the blanks for automatic loading. door.

- Check if there are any objects that prevent the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) from opening and / or closing.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) from opening and / or closing. - Check if there are any objects in the travel range of the carriage in the working chamber and blank magazine

Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading..

Is the mechanism of the blank changer flap damaged?

How to check this:

- Close the working chamber door.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in DentalCNC.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in DentalCNC.- Disconnect the machine from the external compressed air supply.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap closes slowly. A small gap remains. This does not indicate that there is a malfunction.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap closes slowly. A small gap remains. This does not indicate that there is a malfunction. - Open the working chamber door.

- Open the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) by pressing against the top side with you finger [1] and pulling the bottom side with your thumb [2].

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) by pressing against the top side with you finger [1] and pulling the bottom side with your thumb [2]. - Fully open and close the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap with your hand multiple times.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap with your hand multiple times. - The flap opens and closes smoothly.

- Close the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap. - Close the working chamber door.

- Connect the machine to the external compressed air supply.

- Confirm the message in DentalCNC.

Move the axes into the default position by selecting the depicted icon in the Machining view in DentalCNC.

Move the axes into the default position by selecting the depicted icon in the Machining view in DentalCNC.

Manually opening the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Risk of injury caused by the fast moving blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap

If the working chamber door is not closed now, the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap may hit and injure you when you proceed.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap may hit and injure you when you proceed.

Does the corresponding end switch or sensor now send a signal?

How to check this:

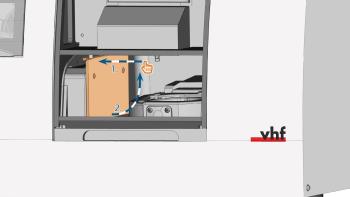

- Manually reset the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to default position. See ‘Manually resetting the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to default position. See ‘Manually resetting the blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to the default position’.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to the default position’. - Start DentalCNC.

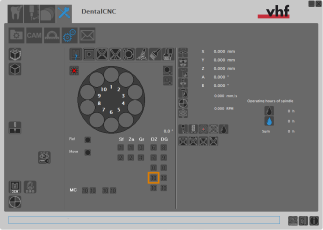

- Open the DentalCNC Application settings. For this, select the following icon in the main icon bar:

- Open the Machine maintenance view. For this, select the following icon in the lower icon bar:

- Verify that the upper icon labeled 10 in the DZ column is highlighted.

Recommendation

If you mount blanks to blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading. slots, immediately assign the corresponding job to the slot in DentalCNC.

Part of the blank changer in which you store the blanks for automatic loading. slots, immediately assign the corresponding job to the slot in DentalCNC.

Never mount a blank into the slot from which the blank that is currently in the working chamber was loaded.

- Remove the blank from the change position (marked orange) of the blank magazine

Part of the blank changer in which you store the blanks for automatic loading.. See ‘Operating the blank changer

Part of the blank changer in which you store the blanks for automatic loading.. See ‘Operating the blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead’.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead’. - Reset the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to default position. See ‘Manually resetting the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to default position. See ‘Manually resetting the blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to the default position’.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead to the default position’. - Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly. - If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

- Clean the blank magazine

Part of the blank changer in which you store the blanks for automatic loading.. See ‘Cleaning the blank magazine

Part of the blank changer in which you store the blanks for automatic loading.. See ‘Cleaning the blank magazine Part of the blank changer in which you store the blanks for automatic loading.’.

Part of the blank changer in which you store the blanks for automatic loading.’. - Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Recommendation

- If components (washers etc.) are missing, do not use the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead. Contact customer service.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead. Contact customer service. - Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

If you were able to properly install the cover plate, continue as follows:

Recommendation

Recommendation

- Remove all objects that block the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead.

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead carriage and blank changer Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap moved steadily and smoothly. - If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

Recommendation

Recommendation

It may have been a temporary issue.

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.