Applies to: DentalCAM & DentalCNC 8.11 / R5

Error code -1000 or -2000 – Error while unloading the blank

This error code can occur while the machine is unloading a blank from the working chamber into the blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading..

It indicates that the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (swivel axis) could not reach its default position.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (swivel axis) could not reach its default position.

The corresponding end switch or sensor did not send a signal.

Interactive troubleshooting guide

Is the blank changer flap (swivel axis) in the default position?

How to check this:

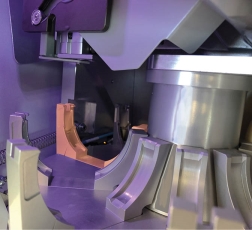

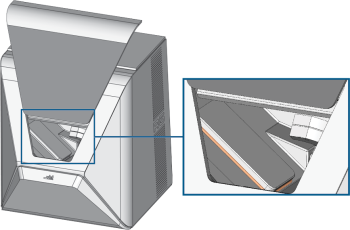

- Compare the position of the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) to the following figure:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) to the following figure:

Blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) in default position

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange) in default position

Did the blank in the blank gripper collide with a blank in the blank magazine?

How to check this:

- Make sure that DentalCNC prompted you to remove the blank from the blank holder before outputting the error code.

- Open the multi-purpose compartment.

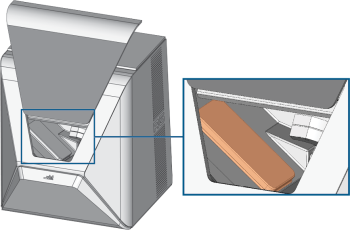

- Locate the loading position on the left side of the blank magazine

Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading.. - Check if there is a blank at the loading position (marked orange).

Does the corresponding end switch or sensor now send a signal?

How to check this:

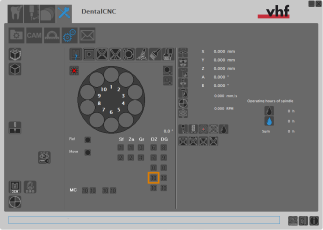

- Start DentalCNC.

- Open the DentalCNC Application settings. For this, select the following icon in the main icon bar:

- Open the Machine maintenance view. For this, select the following icon in the lower icon bar:

- Verify that the upper icon labeled 10 in the DZ column is highlighted.

Is the working chamber and especially the blank changer flap soiled?

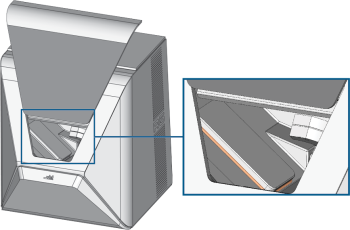

- In particular, check the door at the bottom edge (marked orange).

Bottom edge of the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Are the gripper and blank changer flap (swivel axis) blocked?

How to check this:

- Open the working chamber door.

- In the working chamber:

- Check if there are any objects in the swivel range of the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (swivel axis).

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (swivel axis). - Check if there are any objects in the extension range of the blank gripper.

- Check if there are any objects in the swivel range of the blank changer

- Check if the blank holder including its cracks are soiled by machining debris.

- Open the multi-purpose compartment.

- In the multi purpose compartment:

- Check if there are any objects in the swivel range of the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (swivel axis).

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (swivel axis). - Check if there are any objects in the extension range of the blank gripper cylinder.

- Check if there are any objects in the swivel range of the blank changer

- Check if there are any objects in the loading position of the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. (marked orange).

Part of the blank changer in which you store the blanks for automatic loading. (marked orange).

Does increasing the incoming air pressure solve the issue?

How to check this:

- Open the multi-purpose compartment.

- Remove the cooling liquid tank.

- Use the compressed air regulator (marked orange) to increase the incoming air pressure depending on the discs you use:

- For cobalt-chrome discs: 8 bar (120 psi)

- For other materials: 7 bar (100 psi)

- Load and unload the heaviest disc that you use.

Was the disc diameter too large?

How to check this:

- Open the multi-purpose compartment.

- Open the working chamber door.

- Check whether at least one of the following applies:

- The gripper didn’t properly grab the disc.

- The disc collided with the opening between the compartment and the working chamber.

- The disc diameter is too large. Technical data

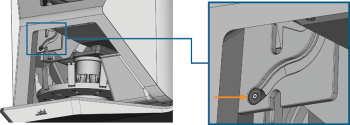

Did the stud type track roller move against the recess of the cam disc?

How to check this:

- Open the multi-purpose compartment.

- Locate the cam disc including the stud type track roller on the upper left side. See the figure below.

- Use your finger to feel if there is a small gap (0.3 – 0.5 mm) between the stud type track roller and the recess of the cam disc.

- If there is no gap, the stud type track roller hit the cam disc.

Due to the perspective, the gap is not visible.

Recommendation

The sensor which detects the position of the swivel axis may need adjustment.

Recommendation

If you mount blanks to blank magazine![]() Part of the blank changer in which you store the blanks for automatic loading. slots, immediately assign the corresponding job to the slot in DentalCNC.

Part of the blank changer in which you store the blanks for automatic loading. slots, immediately assign the corresponding job to the slot in DentalCNC.

Never mount a blank into the slot from which the blank that is currently in the working chamber was loaded.

- Remove the blank from the blank holder.

- Remove the blank from the loading position.

- Clean the blank magazine

Part of the blank changer in which you store the blanks for automatic loading.. Remove all pieces of material that have broken off.

Part of the blank changer in which you store the blanks for automatic loading.. Remove all pieces of material that have broken off. - Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

It may have been a temporary issue.

- Close and restart DentalCNC.

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in DentalCNC.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in DentalCNC.- Open the working chamber door.

- Clean the working chamber. Cleaning the working chamber

- Clean the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap and the opening to the multi-purpose compartment.

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap and the opening to the multi-purpose compartment.- Especially clean the flap at the bottom edge (marked orange).

- Remove all objects within or around the opening which prevent the flap from moving.

Move the axes into the default position by selecting the depicted icon in the Machining view in DentalCNC.

Move the axes into the default position by selecting the depicted icon in the Machining view in DentalCNC.- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Bottom edge of the blank changer![]() Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead flap (marked orange)

Recommendation

- Remove all objects that block the swivel axis and blank gripper.

- Thoroughly clean the blank holder.

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

- Remove the blank from the blank holder.

- Remove all discs with a too large diameter from the blank magazine

Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading.. - Only use discs with the correct diameter.

- Test the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead: - Mount blanks of different materials to all blank magazine

Part of the blank changer in which you store the blanks for automatic loading. slots.

Part of the blank changer in which you store the blanks for automatic loading. slots. - If the following applies, the blank changer

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful:

Machine component which stores multiple blanks in a magazine and which can automatically load them into the working chamber.. When using the search, use a blank changer or a blank magazine instead test is successful: - All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the blank magazine

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Part of the blank changer in which you store the blanks for automatic loading. test was not successful: Contact customer service.

Recommendation

Recommendation

Recommendation

- Contact customer service.