Applies to: dentalcam & dentalcnc 8.12 / R5

Error code -1101 or -2101 – Error while unloading the blank

This error code can occur while the machine is unloading a blank from the working chamber into the .

It indicates that the blank gripper could not reach its end position to remove the blank from the blank holder.

The corresponding end switch or sensor did not send a signal.

Interactive troubleshooting guide

Is the blank properly mounted to the blank holder? Has the gripper properly enclosed the blank?

- Carefully check if the blank is properly mounted to the blank holder.

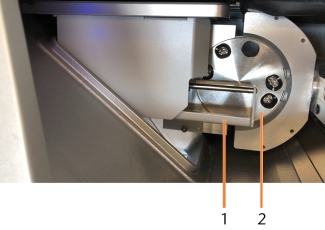

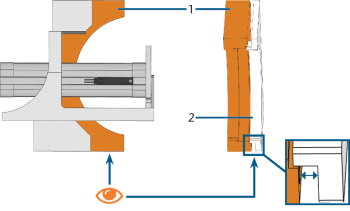

Correct blank unloading process

- Fully extended blank gripper

- Properly mounted blank

- Carefully check if the blank is properly enclosed by the blank gripper.

Properly enclosed blank; area to be checked marked orange

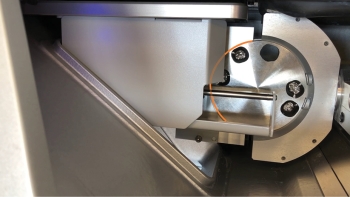

Is the blank gripper fully extended?

Comparison between different blank gripper positions

- Not fully extended blank gripper

- Fully extended blank gripper

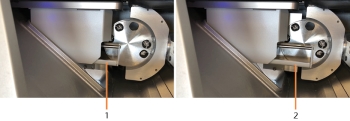

Does the corresponding end switch or sensor now send a signal?

How to check this:

- Start dentalcnc.

- Open the dentalcnc Application settings. For this, select the following icon in the main icon bar:

- Open the Machine maintenance view. For this, select the following icon in the lower icon bar:

- Verify that the lower icon labeled 10 in the DG column is highlighted.

Icon which needs to be highlighted (marked orange)

Is the blank gripper open and/or soiled?

The blank gripper is open by default. If it is closed or soiled, the blank gripper will not be able to grip the blank properly.

How to check this:

- If the blank gripper is not in the working chamber, look through the open flap to the blank gripper.

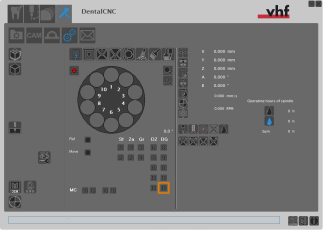

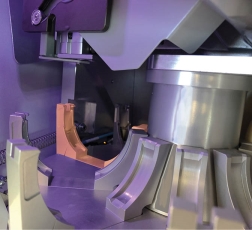

Checking the blank gripper through the flap

- Check whether there is a small even gap between the 2 workholding straps along the entire length of the blank gripper.

: Side view of the blank gripper; : Gap between the workholding straps

- First workholding strap (marked orange)

- Second workholding strap

- If there is a small gap between the 2 workholding straps along the entire length of the blank gripper, the blank gripper is open.

- Check if there are machining residues between the workholding straps.

Did the blank gripper move sluggishly?

Did the blank gripper move sluggishly?

Can you properly open and close the blank holder?

How to check this:

- Open the blank holder by selecting the depicted icon in the Machining view in dentalcnc.

- Remove any blank from the blank holder.

- Check if the following applies:

- The workholding straps are in parallel to each other.

- There is a small even gap between the workholding straps.

Blank holder, 1 workholding strap marked orange; opening/closing direction indicated by the arrows

-

Close the blank holder by selecting the depicted icon in the Machining view in dentalcnc.

- Check if the following applies:

- The workholding straps are in parallel to each other.

- The workholding straps have moved towards each other.

- Open, close and check the blank holder multiple times.

Are the gripper and blank changer flap (swivel axis) blocked?

How to check this:

- Open the working chamber door.

- In the working chamber:

- Check if there are any objects in the swivel range of the flap (swivel axis).

- Check if there are any objects in the extension range of the blank gripper.

- Check if the blank holder including its cracks are soiled by machining debris.

- Open the multi-purpose compartment.

- In the multi purpose compartment:

- Check if there are any objects in the swivel range of the flap (swivel axis).

- Check if there are any objects in the extension range of the blank gripper cylinder.

- Check if there are any objects in the loading position of the (marked orange).

The loading position (marked orange)

Recommendation

- Open the blank holder by selecting the depicted icon in the Machining view in dentalcnc.

- Manually remove the blank from the blank holder.

-

Close the blank holder by selecting the depicted icon in the Machining view in dentalcnc.

- Test the :

- Mount blanks of different materials to all slots.

- If the following applies, the test is successful:

- All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

Recommendation

The sensor may need adjustment.

Recommendation

Recommendation

- Thoroughly clean the blank gripper.

- Test the :

- Mount blanks of different materials to all slots.

- If the following applies, the test is successful:

- All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the test was not successful: Contact customer service.

Recommendation

- Contact customer service.

Recommendation

Recommendation

- Remove all objects that block the swivel axis and blank gripper.

- Thoroughly clean the blank holder.

- Test the :

- Mount blanks of different materials to all slots.

- If the following applies, the test is successful:

- All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

- If the test was not successful: Contact customer service.

Recommendation

- Thoroughly clean the blank holder.

- Test the :

- Mount blanks of different materials to all slots.

- If the following applies, the test is successful:

- All blanks were successfully loaded and unloaded.

- The gripper and swivel axis moved steadily and smoothly.

Recommendation

It may have been a temporary issue.

Recommendation

- Contact customer service.

![]() Part of the blank changer in which you store the blanks for automatic loading..

Part of the blank changer in which you store the blanks for automatic loading..