Applies to: DentalCAM & DentalCNC 8.11

Error code 22 or 23 – Axis not referenced / Not found reference point

DentalCNC aborts the job and displays the error code.

There is an extended version of this troubleshooting guide available for vhf certified service employees:

Interactive troubleshooting guide

When did DentalCNC display the error code?

Does a machine and computer restart solve the issue?

How to check this:

- Restart the machine and the .

- Start DentalCNC.

Is the working chamber clean and free from broken off blank parts?

Is the blank magazine of corresponding machines in the default position?

How to check this:

- Start DentalCNC.

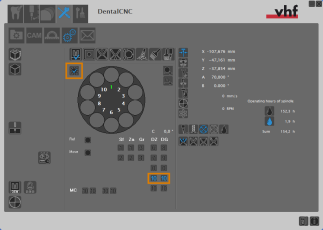

- Open the DentalCNC Application settings. For this, select the following icon in the main icon bar:

- Open the Machine maintenance view. For this, select the following icon in the lower icon bar:

- Verify that the 2 upper icons labeled 10 in the DZ and DG columns are highlighted.

- Verify that the icon to the top left of the illustration are highlighted:

Icons that must be highlighted (marked orange)

Does DentalCNC indicate that an axis moved into an end switch?

How to check this:

- Open the Machining view. For this, select the following icon in the main icon bar:

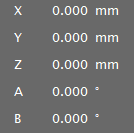

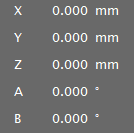

- Check if a red indicator displays next to the axis labels. The red indicator only displays for a short time.

The axis labels in DentalCNC

Can you move the spindle and blank holder along the corresponding axes evenly by hand?

How to check this:

- Open the working chamber door.

- Switch off the machine at the main power switch.

- Move the spindle and blank holder until you reach the end point of the corresponding axis. Stop immediately if you encounter any resistance.

- Carefully move the spindle along the X-, Y- and Z-axis.

- Carefully rotate the blank holder about the A-axis.

- 5-axis machines only: Carefully rotate the blank holder around the B-axis.

Were you able to reach the end points of all axes?

Recommendation

- Remove all objects which block the axes.

- Thoroughly clean the working chamber.

- Machines with a : Remove all objects that block the .

- S2 or S5: If the is not in default position, manually put it into this position.

- Restart the job.

Recommendation

Recommendation

Recommendation

- Switch off the machine at the main power switch.

- Open the working chamber door.

- Move the spindle and the blank holder away from the end points. Stop immediately if you encounter any resistance.

- Carefully move the spindle along the X-, Y- and Z-axis.

- Carefully rotate the blank holder about the A-axis.

- 5-axis machines only: Carefully rotate the blank holder around the B-axis.

- Restart the machine and the .

- Restart the job.

Recommendation

- Follow the guide for a failed axis power test.

Service: Recommendation

- Contact customer service..

Service: Recommendation

- Close the working chamber door.

- Switch on the machine at the main power switch.

- Restart the job.

Recommendation

- Close the working chamber door.

- Restart the job.

Service: Recommendation

- Contact customer service..