Cleaning the machine

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

Damaging of the linear guides or the spindle when cleaning with compressed air

If you clean the working chamber with compressed air, material chips can reach the linear guides or the spindle bearings.

- Never clean the working chamber with compressed air.

Cleaning the working chamber includes the following components:

- Measuring key

- Blank holder

- View window

- Webcam

- Tool magazines

- Tool magazine holder

- Nozzle plate

These components have different maintenance intervals according to the maintenance table. Therefore, depending on the components that need to be cleaned, perform daily or weekly cleaning of the working chamber.

- When performing the weekly cleaning, also perform the daily cleaning.

Performing the daily cleaning

We recommend cleaning the working chamber after all other required maintenance tasks.

Do not pour additional water into the working chamber. The cooling liquid tank may overflow.

- Have ready:

- A wet cloth

- A mild cleaning agent (optional)

- A suction unit

- Small cleaning brush for the blank holder

- Open the working chamber door.

- Thoroughly clean all surfaces and gaps in the working chamber with the damp cloth. Use a mild cleaning agent if necessary.

- Suction any machining residue off of the measuring sensor from a distance of 3 cm.

-

Change the cooling liquid. Exchanging the cooling liquid and cleaning the cooling liquid tank

Cleaning the nozzle plate

Clean the openings in the nozzle plate every time you clean the collet chuck.

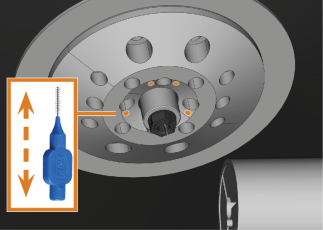

- Have the interdental brush ready.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in dentalcnc.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in dentalcnc.- Open the working chamber door.

-

Clean the smaller openings in the inner area of the nozzle plate. For this, move the interdental brush up and down.

If necessary, apply some water with a cleaning agent and let it sit for some minutes.

Performing the weekly cleaning

- Have ready: The cleaning brush for the blank holder.

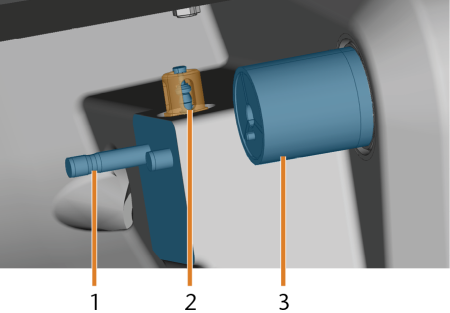

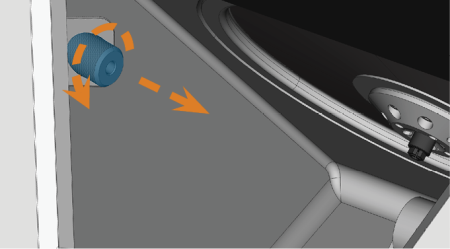

- Remove the tool magazine from the working chamber. Clean it with the cloth and the brush.

- Open the multi-purpose drawer. Clean the other tool magazines.

- Clean the blank holder with its respective brush.

- Screw the protective cap off the webcam and clean the inside of the cap with a dry cloth.

- Clean the webcam with a wet cloth. Screw on the protective cap.

- Clean the tool magazine holder thoroughly.

- Apply a bit of collet chuck grease to the bolts of the tool magazine holder.

- To apply the collet grease to the holes of all tool magazines, mount all tool magazines once.

- Clean the housing. Cleaning the housing