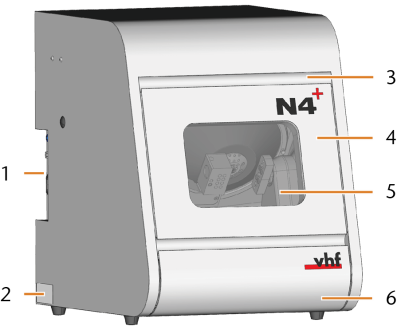

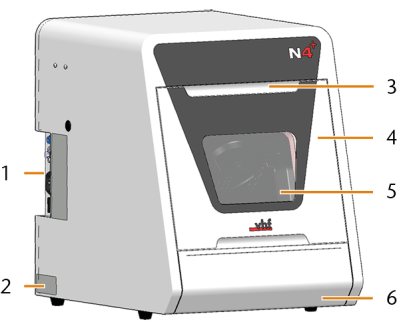

Machine overview

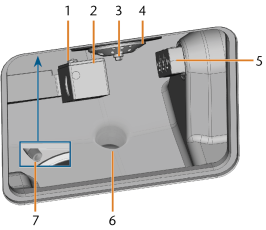

Front side of the machine

- Connection panel and main power switch on the back

- Identification plate

- Recessed grip for opening the working chamber door

- Working chamber door

- View window to the working chamber

- Cooling liquid drawer

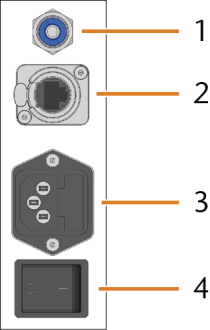

Connection panel

- Pneumatic connection (6 mm push-in fitting)

- Network port (Ethernet RJ-45)

- Power connection including glass fuse T6,3A L250V

- Main power switch

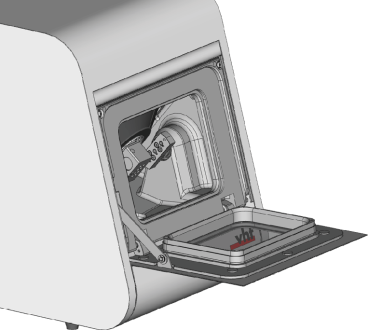

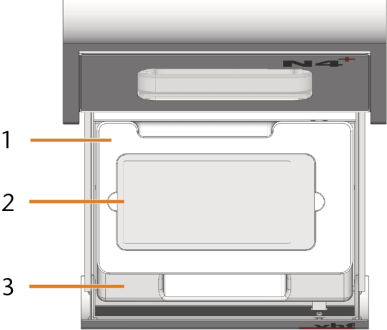

Working chamber door

The working chamber door locks the working chamber and protects the user from injuries during operation.

You cannot open the door when the machine is switched off or while the axes are moving.

Working chamber

You can insert blanks and tools into the working chamber. This is where the blanks are machined.

- Measuring sensor

- Tool magazine

- Spindle

- Nozzle plate

- Blank holder; Rotational axis A

- Outlet for the cooling liquid

- Webcam

Colors of the working chamber lighting

|

Color |

Status |

Working chamber door |

|---|---|---|

|

Green |

The machine is ready for operation. |

unlocked |

|

White |

The machine is ready for operation. |

unlocked |

|

Blue |

|

locked |

|

Red |

A machine malfunction has occured. |

locked |

Cooling liquid drawer

The cooling liquid tank is located in the cooling liquid drawer below the working chamber.

CAM computer

To operate the machine, you must use a computer running Windows® (“CAM computer![]() The computer that is connected to your machine and which runs dentalcam and dentalcnc.”) and specially designed software (“manufacturing software

The computer that is connected to your machine and which runs dentalcam and dentalcnc.”) and specially designed software (“manufacturing software![]() Term for the software package consisting of dentalcam and dentalcnc.”). The manufacturing software

Term for the software package consisting of dentalcam and dentalcnc.”). The manufacturing software![]() Term for the software package consisting of dentalcam and dentalcnc. consists of the following components:

Term for the software package consisting of dentalcam and dentalcnc. consists of the following components:

- dentalcamA CAM application for creating and calculating virtual blanks (“jobs”)

- dentalcncA CNC application for machining jobs and for maintaining the machine.

To create and design the dental objects you also need a CAD application (sold separately by specialist dealers).

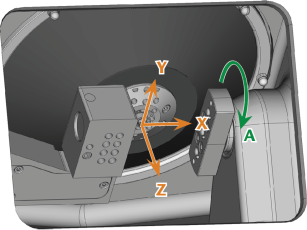

Axes

This machine has

-

Linear axes X, Y, Z

The spindle moves along these axes.

-

Rotational axis A

The blank holder rotates about this axis.

Identification plate and serial number

The identification plate of the machine contains identifying information such as the serial number. You can find the identification plate and machine serial number at the following location: Front side of the machine