Transportation and storage

Injuries caused by unsafe transportation

If you transport the machine unsafely, the machine may slip and cause injuries.

Parts that are not properly mounted can fall and injure you and/or become damaged.

- Ensure that only trained personnel transport the machine to and from the installation site.

- Always transport the machine in an upright position.

- Transport and position the machine with as many people as required for the weight of the machine in accordance with local and / or national laws and regulations.

Machine damage due to improper transport and / or storage

-

Ensure that all conditions set forth in the chapter are met during the entire transport and / or storage period Technical data.

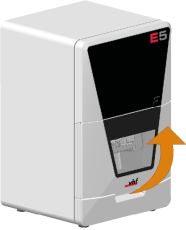

Transporting the machine in the carton

-

Grasp the carton by the recessed grips.

-

Always set the package down during transport so that the arrows on the transport position sticker are pointing upward.

Storing the machine

-

Clean the machine.

-

Switch off the machine at the main power switch.

-

Disassemble the machine components by following the installation instructions in reverse order.

Putting the machine back into operation after storage

-

Follow the instructions for initial start-up.

Packing the machine

Preparing transport

-

Clean the machine. Cleaning the machine

-

In case of overseas transport, take proper measures against corrosion.

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

Packing the machine

-

Have ready:

-

If possible, use the original packaging. If the original packaging is not available, use a packaging of similar size and quality.

Original packaging is available from customer service.

-

CAUTION!Wear gloves.

-

Open the working chamber door.

-

Remove the blank from the blank holder if present.

-

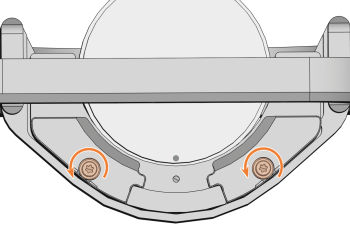

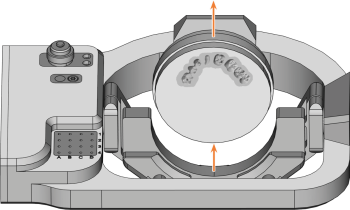

Attach the spindle lock:

-

Loosen the 2 fixing screws on the blank holder without unscrewing them.

-

Insert the spindle lock into the blank holder from above.

-

Tighten the fixing screws with the supplied torque screwdriver (1.5 Nm).

-

Close the working chamber door.

-

Start dentalcnc.

-

Move the spindle to the transport position.

-

Close dentalcnc.

-

Open the working chamber door.

-

DANGER!Switch off the machine at the main power switch.

-

Disconnect the machine from all lines.

-

Slide the working chamber door stoppers onto the edges of the working chamber door.

-

3 x Long version: Centered on the left, right and top edge.

-

2 x Short version: On the lower edge to the left and right of the recessed grip.

The short versions were not supplied with older machines. In this case, leave the bottom edge free.

-

-

If Customer Service has asked you to send in accessories, stow the items in the accessory boxes.

-

Push the 5 parts of the transport lock into the working chamber without turning the A-B axis module.

-

Clamp the left transport lock on the left working chamber wall under the A-B axis module.

-

Clamp the right transport lock on the right working chamber wall under the A-B axis module.

-

Clamp the middle parts under the A-B axis module:

-

Accessory box 1 (bottom)

-

Accessory box 2 (center)

-

Accessory cover (top)

-

-

-

Pull the working chamber door down.

-

The working chamber door stoppers prevent the working chamber door from closing completely.

-

Position the transport box on a surface that can support the machine weight including the packing set.

-

Open the box at the front with the label Open here.

-

Recommendation: The back of the carton should touch a solid wall. Otherwise, you will need a 2nd person for inserting the machine.

-

-

Place the inserter in front of the transport carton such that the handle (marked green) is on the opposite side of the carton opening.

-

Spread out the blue transport protection cover evenly on the inserter with the opening facing upward.

-

Position the bottom cushion centrally in the transport protection hood.

-

Press down the transport protection hood on all sides such that the surface of the bottom cushion is exposed.

-

Grasp the machine with 2 persons by the left and right handles on the underside of the machine.

-

Lift the machine into the bottom cushion:

-

The back of the machine points towards the carton opening.

-

The left and right recessed grips in the bottom cushion provide room for your hands.

-

-

Place the protective housing cover over the machine from above.

-

Place the top cushion on the machine top.

-

Pull the transport protection hood over the machine on all sides until the ends meet in front of the working chamber door.

-

Tape the ends of the transport protection hood together with adhesive tape.

-

If the back of the transport carton is not in contact with a solid wall, have a 2nd person hold the carton in place.

-

Slowly slide the machine including the inserter into the transport box.

The machine must not slip off the inserter.

-

Close the transport box.

-

Tape the closing flaps together with adhesive tape.

-

To carry the transport box, grasp the box by the recessed grips with 2 persons.

-

To ship the machine with a shipping company, lift the shipping carton onto a pallet.

-

Attach the transport box to the pallet:

-

Attach 2 edge protection corners each to the left and right of the recessed grips.

-

Strap the pallet and the transport box with the 1st strap.

- Guide the strap over 2 opposite edge protection corners.

-

The ends of the strap must meet on the top of the carton.

-

Create a loop with each end of the strap and guide each one through the buckle.

-

Flip the two pins on the buckle over toward the buckle opening.

-

Fixate 1 loop to 1 pin at a time and tighten the loops.

-

Pull both ends of the strap at the same time so that the strap is tight against the shipping carton.

-

Shorten the protruding ends of the strap with scissors.

-

Guide the 2nd strap over the 2 edge protection corners and repeat the previous steps.

-

-

The straps secure the transport box against slipping.

-

If you do not use the supplied straps, protect the shipping carton against slipping in some other way.

NOTICE! Damage to the A-B axis module as well as the spindle due to rotation of the A-B axis module