Exchanging the spindle unit

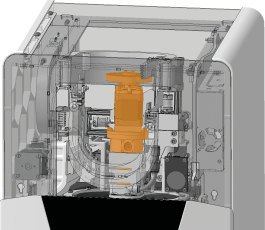

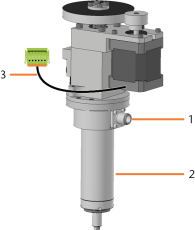

When exchanging the spindle, exchange the entire spindle unit, which consists of the following components:

-

Spindle including collet chuck

-

Collet chuck release unit including cable

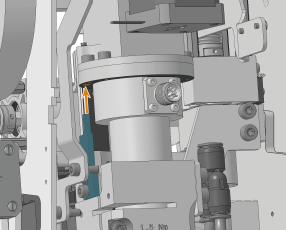

The spindle unit (marked orange) is located behind the service cover.

-

Have ready:

-

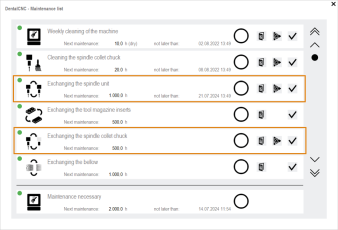

Start dentalcnc.

- Open the Maintenance section with the following icon in the main toolbar:

-

The spindle moves into the spindle exchange position.

-

Close dentalcnc.

-

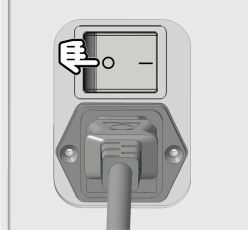

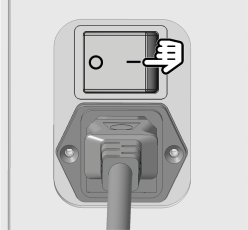

.Switch off the machine at the main power switch.

-

Disconnect the machine from all lines.

-

Remove the service cover,

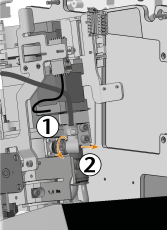

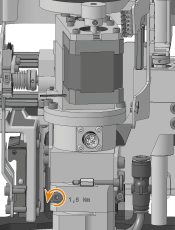

- Loosen the spindle cable by manually turning the knurled nut anti-clockwise.

-

Pull the spindle cable out of the connector on the spindle unit.

-

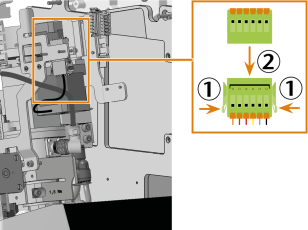

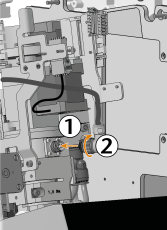

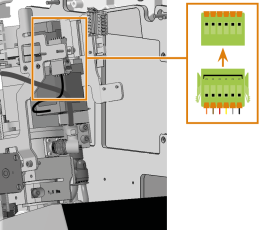

Remove the collet chuck release unit cable:

Push both mounting clips on the connector toward the center and pull the connector out of the socket.

-

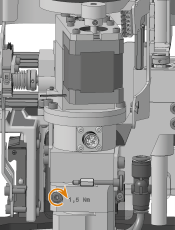

Loosen the fixing screw with the torque screwdriver. Do not unscrew the screw completely.

-

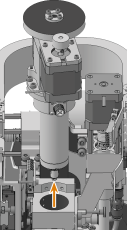

Pull the spindle unit upward out of the spindle holder.

-

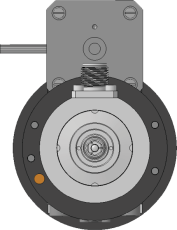

Pick up the spare spindle unit and locate the positioning pin hole (marked orange) on the bottom.

-

Turn the spindle unit such that the positioning opening (marked orange) is located at the rear left.

-

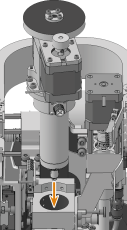

Insert the spare spindle unit into the spindle holder from above:

-

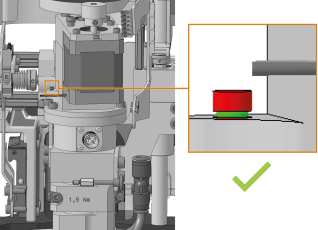

Insert the positioning aid (marked blue) on the spindle holder into the positioning hole (marked orange) in the spindle.

-

Gently push the spindle down, paying attention to the spindle height display.

NOTICE! Make sure that the spindle gear does not touch the cooling liquid hose.

-

-

Once you have pushed the spindle down sufficiently, you will see the green ring on the spindle height display.

-

Use the torque screwdriver to tighten the screw for holding the spindle in place.

-

Plug the spindle cable into the spindle connector.

-

Tighten the spindle cable by manually turning the knurled nut clockwise.

-

Insert the collet chuck release unit cable into the corresponding connector in the machine.

-

Attach the service cover.

-

Switch on the machine at the main power switch.

-

Start dentalcnc.

- Open the Maintenance section with the following icon in the main toolbar:

-

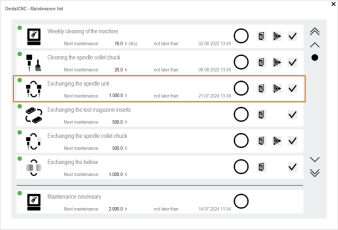

Select the following icon of the entries Exchange spindle and Exchange spindle collet chuck:

-

Mill a test specimen and calibrate the machine as necessary.

-

Contact customer service and have the spindle operating hours reset.

This can be important for deciding warranty claims.