Cleaning the collet chuck of the spindle

This description applies to cleaning and replacing the collet chuck. A new collet chuck does not need to be cleaned with the brush before installation.

Damaging of the spindle when cleaning with compressed air

If you clean the collet chuck with compressed air, the spindle bearings can be damaged.

- Clean the collet chuck only with the appropriate service set.

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

-

Have the following items from the machine's accessories ready:

-

Clamping wrench

-

Open-end wrench

-

Cleaning cone

-

Cleaning brush for the collet chuck

-

Move the axes into the tool change position by selecting the depicted icon in the Machining view in dentalcnc.

Move the axes into the tool change position by selecting the depicted icon in the Machining view in dentalcnc.-

CAUTION!Wear gloves.

- Open the working chamber door.

-

Remove the tool from the collet chuck.

-

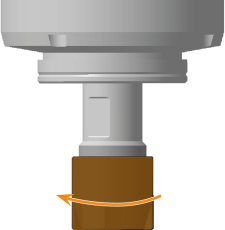

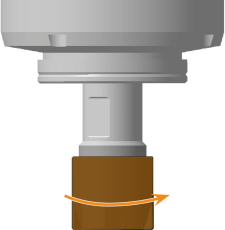

Turn the clamping nut (marked orange) counterclockwise completely off the spindle and remove it from the machine along with the collet chuck (marked blue).

-

Put the clamping nut and the collet chuck aside within reach.

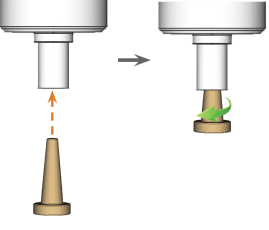

- Clean the inner cone of the spindle with the cleaning cone.

-

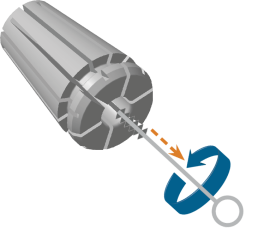

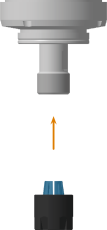

Take the collet chuck (marked blue) out of the clamping nut.

-

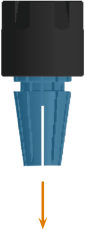

Clean the collet chuck with the cleaning brush:

-

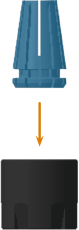

Insert the brush into the collet chuck until the end of the brush aligns with the end of the collet chuck.

-

Rapidly pull the brush out of the collet chuck and twist it at the same time.

-

Repeat the last 2 steps multiple times.

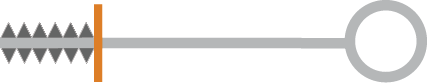

End of brush marked with a vertical orange line

-

-

Thoroughly clean the complete outer surface of the collet chuck with a clean and dry cloth.

-

Place the collet chuck (marked blue) in the clamping nut and turn the clamping nut (marked orange) by hand approx. 1 turn clockwise onto the spindle.

NOTICE! Turn the clamping nut just enough that it remains on the spindle. Never tighten the tension nut firmly without having a tool inserted.

-

Put the tool back into the collet chuck.

-

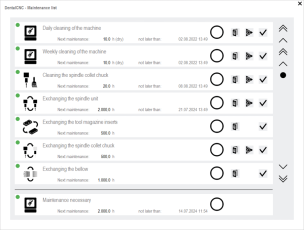

Open the Maintenance section with the following icon in the main toolbar:

-

Select the icon shown for the entry Cleaning the collet chuck of the spindle.

Select the icon shown for the entry Cleaning the collet chuck of the spindle.