Applies to: dentalcam & dentalcnc 8.12

Error code -13 – Insufficient compressed air

dentalcnc aborts the job and displays the error code.

Interactive troubleshooting guide

Is the outgoing air pressure at the compressed air regulator correct?

This procedure doesn’t apply to Z4 machines as they have an internal compressed air supply.

- If the machine is a Z4, select I use a Z4.

How to check this:

- Locate the compressed air regulator.

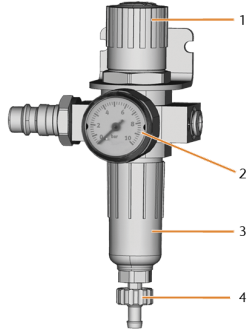

- Rotary knob for pressure regulation

- Pressure gauge for monitoring the outgoing air pressure

- Bowl of the water separator

- Discharge screw

- Compare the pressure value displayed on the pressure gauge to the requirements of your machine. Technical data: Side-by-side comparison

Is the compressed air regulator correctly connected to the machine?

This procedure doesn’t apply to R5 machines as they have an internal compressed air regulator.

- If the machine is a R5, select I use an R5.

How to check this:

- Locate the hose which connects the compressed air regulator to the machine.

- Check the hose for the following:

- Leakage

- Kinks

- The hose must not be trapped.

- The hose must be properly seated in the connections.

Does dentalcnc indicate that the air pressure is sufficient?

How to check this:

- Open the Machining view. For this, select the following icon in the main icon bar:

- Check whether the following icon is highlighted:

Icon which needs to be highlighted (marked orange)

Does adjusting the pressure with the compressed air regulator solve the issue?

How to check this:

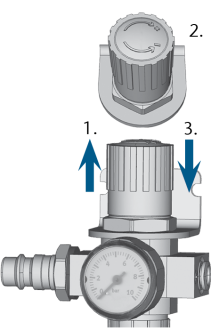

- Use the rotary knob to adjust the air pressure. It must meet the requirements of the machine. Technical data: Side-by-side comparison

- Rotary knob for pressure regulation

- Pressure gauge for monitoring the outgoing air pressure

- Bowl of the water separator

- Discharge screw

- Check if dentalcnc indicates that the air pressure is sufficient.

- Open the Machining view. For this, select the following icon in the main icon bar:

- Check whether the following icon is highlighted:

Icon which needs to be highlighted (marked orange)

Is the machine properly connected to the external air supply? Are all required valves open?

How to check this:

- Locate the compressed air hose which connects the external air supply to the machine (R5) or the compressed air regulator (all other machines).

- Check the hose for the following:

- Leakage

- Kinks

- The hose must not be trapped.

- The hose must be properly seated in the connections.

- Check if all required compressed air valves are open.

Is the outgoing pressure of the compressor correct?

How to check this:

- Make sure that the compressor is switched on.

-

Compare the pressure value displayed on the pressure gauge of the compressor to the requirements of your machine.

The pressure should be at least as high as the maximum pressure for your machine. Technical data: Side-by-side comparison

Is more than 1 device connected to the compressor?

Recommendation

- Tauschen Sie alle beschädigten Schläuche aus.

- Verlegen Sie die Schläuche so, dass sie keine Knicke aufweisen und nicht eingeklemmt sind.

- Stellen Sie sicher, dass alle Schläuche richtig in den Anschlüssen sitzen.

Recommendation

The compressed air pressure sensor, internal hoses and compressed air pumps must be checked.

Recommendation

Recommendation

- Tauschen Sie alle beschädigten Schläuche aus.

- Verlegen Sie die Schläuche so, dass sie keine Knicke aufweisen und nicht eingeklemmt sind.

- Stellen Sie sicher, dass alle Schläuche richtig in den Anschlüssen sitzen.

- Öffnen Sie alle erforderlichen Ventile der Druckluftversorgung.

Recommendation

The compressor may not be able to maintain a sufficient continual flow of compressed air.

If this does not resolve the issue, check your compressor for its general suitability:

- Check if your compressor meets the requirements as described in the machine’s operating instructions.

- If the compressor doesn’t meet all requirements, exchange it for a suitable compressor.

- If the compressor meets all requirements:

Recommendation

The compressor may not be able to maintain a sufficient continual flow of compressed air.

If this does not resolve the issue, check your compressor for its general suitability:

- Check if your compressor meets the requirements as described in the machine’s operating instructions.

- If the compressor doesn’t meet all requirements, exchange it for a suitable compressor.

- If the compressor meets all requirements:

Recommendation

The compressor may not be able to supply all connected devices with sufficient compressed air.

-

Adjust the outgoing air pressure of the compressor.

The pressure should be at least as high as the maximum pressure for your machine. Technical data: Side-by-side comparison

- Disconnect all devices but the machine from the compressor.

If this does not resolve the issue, check your compressor for its general suitability:

- Check if your compressor meets the requirements as described in the machine’s operating instructions.

- If the compressor doesn’t meet all requirements, exchange it for a suitable compressor.

- If the compressor meets all requirements:

Recommendation

The compressor may not be able to maintain a sufficient continual flow of compressed air.

- Check if your compressor meets the requirements as described in the machine’s operating instructions.

- If the compressor doesn’t meet all requirements, exchange it for a suitable compressor.

- If the compressor meets all requirements: