Operation

Machine damage due to humid air or residual water

-

Activate the extraction system of the milling machine during and after wet machining.

-

Leave the working chamber door open when you finish machining.

Switching from dry to wet machining

-

Clean the working chamber of the milling machine.

-

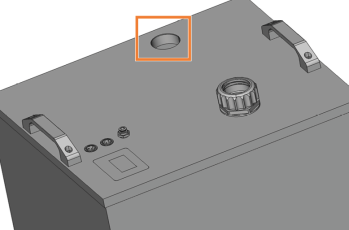

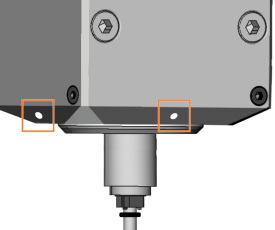

Remove the suction hose from the milling machine and insert it into the suction port (marked orange) on the wet grinding module.

-

Insert the connecting hose into the suction port on the milling machine.

-

Activate the cooling liquid pump in dentalcnc.

-

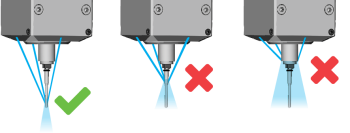

Check if sufficient cooling liquid is hitting the cutting edge from all 3 spindle nozzles.

-

Deactivate the cooling liquid pump.

-

The wet grinding module is ready for use.

Using the wet grinding module

-

Operate the wet grinding module with the suction switched on at the highest level.

-

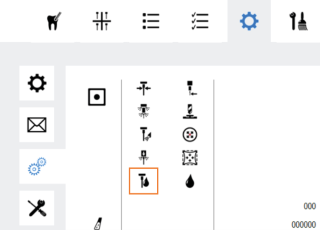

Make sure that the icon for wet machining is activated when you create a job. The software then automatically controls the wet grinding module during machining.

dentalcam activates this function automatically for materials that must be processed wet (e.g. ceramic materials).

-

Drops may form on the surface of the wet grinding module during prolonged operation. This is not a malfunction. Remove moisture regularly and check that all hoses are connected correctly.

Switching from wet to dry machining

-

Activate the extraction system.

-

Open the working chamber door of the milling machine.

-

Remove all blanks from the milling machine.

-

Push the liquid in the working chamber towards the air extraction opening.

-

Remove the remaining moisture from the working chamber with a wet suction unit or a cloth.

-

Thoroughly clean the cooling liquid outlet with the cleaning brush.

-

Clean the 3 cooling liquid nozzles of the spindle with an interdental brush.

-

Remove the connecting hose from the milling machine.

-

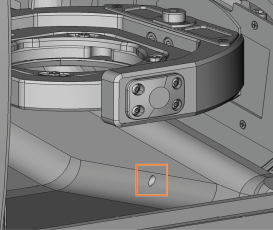

Remove the suction hose from the wet grinding module.

-

Insert the suction hose into the suction port on the milling machine.