Applies to: Dental machines

Deterioration of machining results caused by an incorrect calibration

At delivery, your machine is already calibrated. As long as your machining results are accurate, a new calibration is not necessary. A calibration takes much time and will deteriorate the machining results if it is improperly executed.

- If the machining results are inaccurate, first try to adjust the machining conditions: Check the fixation and quality of the blank and the condition of the tool.

- Before calibrating the machine, contact customer service.

- Be very careful when measuring and entering data during calibration. When in doubt, abort the calibration.

By calibrating the machine with test and calibration specimens, it may be possible to improve the machining results.

The documentation for the manufacturing software![]() Term for the software package consisting of dentalcam and dentalcnc. contains all information for the calibration of the machine. In this document, you will only find machine-specific information.

Term for the software package consisting of dentalcam and dentalcnc. contains all information for the calibration of the machine. In this document, you will only find machine-specific information.

Your machine is delivered with a calibration set. It contains the following parts:

- Calibration blanks which are used to mill calibration and test specimens

- A tool for milling the calibration or test specimens

- A micrometer for measuring the machining precision

Calibration workflow

-

Have the calibration set readily available

The set was provided with your machine.

-

Manufacture and measure a test specimen

If the measuring values are within tolerance, your machine mechanics are accurate and you do not need to calibrate the machine. If they are out of tolerance, continue with calibrating the machine.

-

Manufacture and measure a calibration specimen and enter the values into dentalcnc

This data is used to calculate the required calibration.

-

Check if calibration was successful with another test specimen

Verify that the calibration has improved the machining results.

E3 / N4+:

Fastening the calibration blank in the working chamber

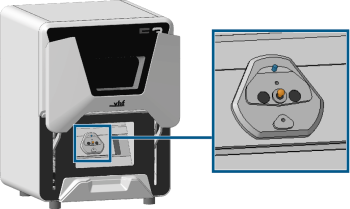

E3

-

Align the calibration blank such that the fastening holes (marked orange) point upwards with the flattened side.

-

Place the elongated hole of the calibration blank on the positioning pin (marked blue) of the blank holder and guide the middle hole onto the pressure piece (marked orange) of the blank holder.

-

Screw the calibration blank tight with 2 of the supplied countersunk screws.

N4+

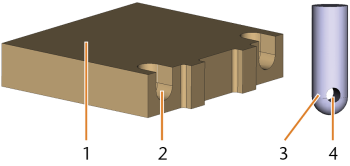

To be able to mount the calibration blanks in the working chamber, you must prepare them.

- Blank

- Recess for shaft

-

Shaft for fastening the blank in the blank holder

-

Opening for the screw used to fasten the shaft

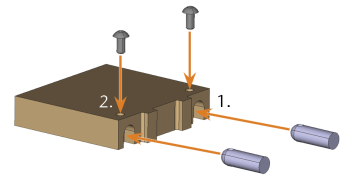

Tool breakage or incorrect results caused by loose screws

If the blank is not properly seated in the blank holder, the measurement results may be incorrect or the tool may break when calibrating.

- Screw the shafts tightly into the blank.

- Screw the blanks tightly into the blank holder.

- Insert the shafts into the recesses in the blank and align the openings for the screws with the corresponding openings in the blank.

- Place the screws in the openings of the blank and screw down the shafts tightly.

E4

Mounting the calibration blank in the blank holder

-

Insert the shaft of the block into the blank holder as far as it will go.

-

Turn the calibration blank so that the positioning pin at the blank holder lies in the groove in the calibration blank.

-

Carefully turn the fixing screw with the screwdriver until you feel a slight resistance.

-

Then turn the fixing screw another 1⁄4 turn.