Cleaning the machine

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

Breathing difficulties caused by machining dust

If machining dust gets into your lungs, this can cause breathing difficulties.

- After dry machining, only clean the machine if the air extraction system is properly installed and activated.

- Wear a face mask of class FFP2 during the entire cleaning.

- Never clean the machine with compressed air.

Risk of injury due to splinters

When cleaning with compressed air, splinters can be thrown around and injure you.

- Never clean the machine with compressed air.

Damaging of the linear guides or the spindle when cleaning with compressed air

If you clean the working chamber with compressed air, material chips can reach the linear guides or the spindle bearings.

- Never clean the working chamber with compressed air.

Cleaning the working chamber includes the following components:

- Measuring key

- Blank holder

- View window

- Tool magazines

- Tool magazine holder

- Nozzle plate

Performing the weekly cleaning

-

Have ready:

-

Close the working chamber door.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in dentalcnc.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in dentalcnc.-

Open the working chamber door.

-

Clean the view window from the inside with a cloth. Use a mild cleaning agent if necessary.

-

Clean all surfaces and cracks in the working chamber thoroughly with the dry cloth. Use a mild cleaning agent if necessary.

-

Clean the working chamber door seal thoroughly with the damp cloth. Use a mild cleaning agent if necessary.

-

Clean the sealing lip, the contact surface and the frame of the view window thoroughly with the damp cloth. Use a mild cleaning agent if necessary.

-

Remove the drain insert and the cooling liquid tank. Clean the drip slide thoroughly from the bottom with the damp cloth. Use a mild cleaning agent if necessary.

-

Clean the sealing lip on the cooling liquid tank thoroughly with the damp cloth. Use a mild cleaning agent if necessary.

-

If necessary, clean the working chamber door seal, the sealing lip of the cross brace, the contact surface, the frame surface of the view window, the drip slide and the sealing lip of the return mat with TecPowder.

-

CAUTION!Pay attention to the label on the packaging of the TecPowder and wear personal protective equipment.

-

Mix some TecPowder with water (mixing ratio 1:40).

-

Soak a cloth in the TecPowder solution and remove contamination.

- Working chamber door seal

- Sealing lip of cross brace

- Contact surface

- Frame surface of view window

- Sealing lip of return mat

- Drip slide

-

-

Clean the nozzle plate:

- Clean the nozzle plate with a damp cloth.

- Clean the 2 opposite openings (marked orange) in the nozzle plate with the interdental brush. Move the interdental brush up and down.

If necessary, apply some water with a cleaning agent to the surfaces and let it sit for some minutes.

-

Clean the blank holder from all sides with a damp brush. First of all, clean the opening of the blank holder.

-

Clean the measuring sensor:

- Remove the cover of the measuring sensor.

-

Clean the measuring sensor and cover of the measuring sensor thoroughly with a damp cloth. Use a mild cleaning agent if necessary.

-

Reattach the cover of the measuring sensor:

- The cover of the measuring sensor is attached magnetically.

-

The cover of the measuring sensor must be flush with the underlying surface and must not be twisted.

-

Tools must be able to push the measuring sensor completely down through the opening in the cover of the measuring sensor.

-

Clean the tool magazine and the tool magazine holder:

-

Remove the tool magazine from the working chamber.

-

Remove all tools from the tool magazine.

-

Clean the tool magazine thoroughly from all sides with the cloth.

-

Clean the drillings for the tool magazine holder with an interdental brush.

-

Clean the tool magazine holder thoroughly with the cloth.

-

Apply a bit of collet chuck grease to the bolts of the tool magazine holder.

-

Place the tool magazine on the tool magazine holder.

-

-

Close the working chamber door.

-

Clean the housing:

-

Clean the surface with a dry microfiber cloth.

Be careful not to detach the symbol stickers. The adhesive foil is especially sensitive to friction and harsh cleaning agents.

-

If some dirt cannot be removed this way, moisten the cloth. Use a pH neutral cleaning agent if necessary.

-

Avoid exposing the surface to alkaline or acidic substances. Especially metallic powders show a highly sensitive reaction.

-

If a special cleaning agent is used to remove certain impurities, check the suitability of the agent in advance at a hidden location on the painted part.

-

NOTICE! Housing damage caused by incorrect aids and cleaning

-

- Open the Maintenance section with the following icon in the main toolbar:

-

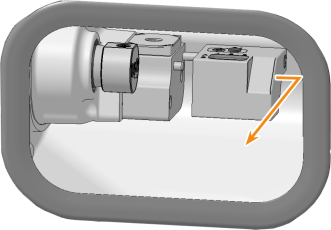

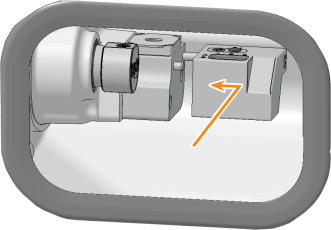

Select the icon shown for the Weekly machine cleaning entry.

Select the icon shown for the Weekly machine cleaning entry.

-

Have ready:

-

Close the working chamber door.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in dentalcnc.

Move the axes into the cleaning position by selecting the depicted icon in the Machining view in dentalcnc.-

Open the working chamber door.

-

Suck up the coarse dirt in the working chamber with the vacuum cleaner.

-

Clean the view window from the inside with a cloth. Use a mild cleaning agent if necessary.

-

Clean all surfaces and cracks in the working chamber thoroughly with the dry cloth. Use a mild cleaning agent if necessary.

-

Clean the working chamber door seal thoroughly with the damp cloth. Use a mild cleaning agent if necessary.

-

Use the brush to clean the blank holder from all sides. First of all, clean the opening of the blank holder.

-

Clean the measuring sensor:

- Remove the cover of the measuring sensor.

-

Suck the machining residues from the measuring sensor.

-

Reattach the cover of the measuring sensor:

- The cover of the measuring sensor is attached magnetically.

-

The cover of the measuring sensor must be flush with the underlying surface and must not be twisted.

-

Tools must be able to push the measuring sensor completely down through the opening in the cover of the measuring sensor.

-

Clean the tool magazine and the tool magazine holder:

-

Remove the tool magazine from the working chamber.

-

Remove all tools from the tool magazine.

-

Clean the tool magazine thoroughly from all sides with the cloth.

-

Clean the drillings for the tool magazine holder with an interdental brush.

-

Clean the tool magazine holder thoroughly with the cloth.

-

Apply a bit of collet chuck grease to the bolts of the tool magazine holder.

-

Place the tool magazine on the tool magazine holder.

-

-

Close the working chamber door.

-

Clean the view window with a cloth. Use a mild cleaning agent if necessary.

-

Clean the housing:

-

Clean the surface with a dry microfiber cloth.

Be careful not to detach the symbol stickers. The adhesive foil is especially sensitive to friction and harsh cleaning agents.

-

If some dirt cannot be removed this way, moisten the cloth. Use a pH neutral cleaning agent if necessary.

-

Avoid exposing the surface to alkaline or acidic substances. Especially metallic powders show a highly sensitive reaction.

-

If a special cleaning agent is used to remove certain impurities, check the suitability of the agent in advance at a hidden location on the painted part.

-

NOTICE! Housing damage caused by incorrect aids and cleaning

-

- Open the Maintenance section with the following icon in the main toolbar:

-

Select the icon shown for the Weekly machine cleaning entry.

Select the icon shown for the Weekly machine cleaning entry.