What's new in dentalcam and dentalcnc?

New functions | Improvement of an existing function | Bug Fixes

Highlights

dentalcam & dentalcnc

Divergent bores can be machined with immediate effect

By extending the 5-axis machining, divergent drillings in discs and blocks can now be ground on 5-axis machines.

(N4, N4+) Added new holder for prefabricated abutments: Organic pre-milled -Ti

If the holder is activated in the list of blank types , you can now choose Organical Pre-milled -Ti from the Blank type drop-down list when creating a blank.

To see which abutments can be used with this holder, filter the list of supported prefabricated abutments by this holder: Supported prefabricated abutment blanks in dentalcam 8

dentalcam

Improved shared blank archive for different machine types

Until now, you could only use the same machine types with a shared blank archive.

You can now use different machine types with a shared blank archive thanks to the improved archive function.

Example: Current situation

You can only resume machining a disc that has already been partially machined on one R5 machine on another R5 machine.

Example: New possibilities with 8.03 and higher

You can resume machining a disc that has already been partially machined on one K5 machine on another 5-axis machine (for example, R5).

We provide you with a stencil for the different mounting positions of the machine types. [Read more]

dentalcnc

New firmware version added

The following new firmware versions are now included in dentalcnc:

| K5 / K5+ | N4 /N4+ | R5 | S1 / S2 / S5 | Z4 |

|---|---|---|---|---|

|

10.86.057 |

||||

NOTICE! Incorrect machining results due to incorrect firmware version

-

Install the most current firmware version for your machine right after updating dentalcam & dentalcnc.

Additional features and changes

dentalcam

P200-R1-35/40 is new standard tool for plastic machining

This change is only applicable to a new installation.

Changing the standard plastic machining tool to P200-R1-35/40 increases process reliability.

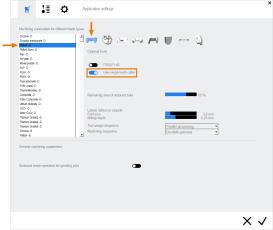

You can also use the previous standard tool, P200-R2-35/40, by deactivating the Use cutter option in the general editing settings for PMMA.

New maximum and minimum values for fit oversizes

Fit oversizes for drillings can now be set from -0.2 mm to +0.2 mm.

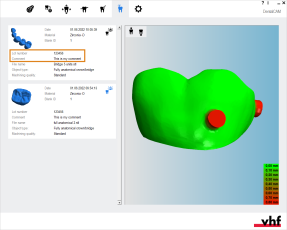

Residual material display: Currently selected object is now more visible

From now on, the permanently highlighted icon in the residual material display shows the object currently selected.

Scaling factors must now be confirmed when creating a blank

Once you add a new blank to the blank archive, dentalcam requires confirmation or correction of the scaling factor for certain blank types.

This prevents the default scaling factor from being adopted unchecked.

dentalcnc

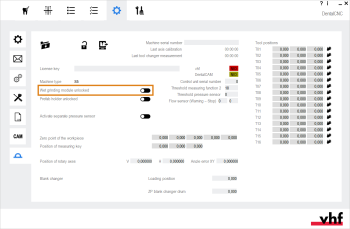

Unlocking the wet grinding module has been simplified

Until now, the wet grinding module had to be activated in dentalcnc by code.

From now on, your customer service will do it for you.

Pneumatic valves now closed during job interruption and / or machine malfunction

If jobs are automatically interrupted or aborted, the pneumatic valves of the machine are closed immediately. This avoids unnecessary consumption of compressed air in the event of machine standstill.

When confirming maintenance tasks in the maintenance section, axes now move to the default position

When you mark maintenance tasks in the maintenance section as completed, the axes return to their default position and the compressed air nozzles are deactivated. This allows you to perform additional maintenance tasks without leaving the maintenance section.

(R5) Improved spindle position for maintenance of spindle collet chuck

![]() The spindle position for maintenance of the spindle collet chuck, which you approach with the icon shown, is now much more accessible.

The spindle position for maintenance of the spindle collet chuck, which you approach with the icon shown, is now much more accessible.

(K5, K5+, N4, N4+, R5, Z4) Improved color for the working chamber lighting

Improved lighting during machining now helps you see what’s happening in the working chamber more clearly.

Bug Fixes

dentalcam

Display of lot number and comment in the residual material display

The residual material display did not show the lot number and comment for the related job.

This behavior has been corrected.

Labels milled on objects can be edited in the nesting view again

dentalcam displays the input field in the nesting view for editing milled labels in the background.

This behavior has been corrected.

Blank type Vita CAD-Temp multiColor -B is correctly calculated again

Errors occurred when jobs with the Vita CAD-Temp multiColor -B blank type were calculated. These also prevented proper machining.

This behavior has been corrected.

Strategy for tools with diameter of 0.6 mm corrected

A non-optimal strategy for tools with 0.6 mm diameter (e.g. U060-R2-35/40) could lead to machining errors, especially in the case of tooth spaces and bars.

This behavior has been corrected.

Grooves on objects no longer occur

With some objects, grooves occurred on the objects due to connections between milling paths.

This behavior has been corrected.

dentalcnc

(Z4 with integrated workflow) Transfer of quality setting from exocad ChairsideCAD and TRIOS Design Studio to dentalcnc now works correctly

The machining quality selected in exocad ChairsideCAD or TRIOS Design Studio was machined incorrectly by dentalcnc. The object was machined at a lower setting.

This behavior has been corrected.