Maintaining the machine with the maintenance section

Is there a list with all maintenance tasks for my machine in DentalCNC? Is there a time display to see when machine maintenance is due?

Keeping track of all maintenance tasks for your machine and their corresponding due dates can be a bit tedious. That’s why we implemented a maintenance section into which does the job for you. The maintenance section allows you to do the following:

- See when the individual maintenance tasks are due

- Mark them as complete to keep the list up to date

- Access online guides to help you with the tasks

- Execute necessary machine functions for individual tasks

Z4: To maintain the machine, only use the maintenance section on the touchscreen and not the one in DentalCNC.

-

Switch on the machine at the main power switch.

-

Open the Maintenance section window with the following icon in the main icon bar:

A red dot in the icon indicates that at least 1 maintenance task is due:

- The maintenance section opens in a new window.

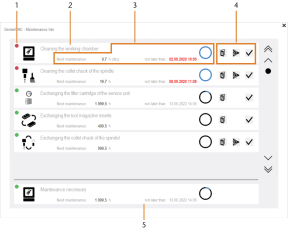

Color indicators

The color indicators in the top left corner of each list entry tell you how urgent the corresponding maintenance task is:

No action is currently needed

The task will be due soon

The task is due. Carry it out as soon as possible.

Time values

The maintenance section contains the following information:

-

Next maintenance: – This text is followed by the remaining operating hours until the corresponding task is due.

If (wet) or (dry) is added to the number of hours, the number only refers to the operating time in the corresponding machining mode (either wet machining or dry machining).

10.0 h (wet) means that the task will be due after 10 hours of wet machining. Dry machining will not affect the remaining hours.

20.0 h means that the task will be due after 20 operating hours, no matter if you process wet or dry jobs.

You can find the maximum number of operating hours (“maintenance interval”) for each task in the maintenance table in the machine’s operating instructions.

-

not later than: – This text is followed by the latest date on which the corresponding task is due, independently of the operating hours.

-

Circles The circles visually indicate how many operating hours have passed since the corresponding maintenance task was marked as complete:

A fully blue circle indicating a due task

A fully black circle indicating a task with maximum remaining operating hours

Icons for maintenance tasks

Marking maintenance tasks as complete

As soon as you have carried out a maintenance task, you should mark it as complete in the maintenance section. This will keep the list up-to-date.

- To mark a task as complete and reset the operating hours to the maximum value, select the following icon:

- The list is updated immediately.

Accessing online guides for basic maintenance tasks

Online guides for basic maintenance tasks are machine-specific Help Articles which contain step-by-step instructions for the corresponding task. An Internet connection is required to view them. The guides are not available for all machines.

- To access an online guide for a maintenance task, select the following icon:

- If a guide is available, the default web browser launches and the corresponding guide displays. Otherwise, displays a corresponding message.

Executing necessary machine functions for individual tasks

Some maintenance tasks are machine-assisted.

The maintenance task requires the collet chuck to be opened by the machine.

- To execute a machine function for a maintenance task, select the following icon:

- The machine executes the required function immediately.

Entry for Preventive maintenance

The separate section at the bottom contains the Preventive maintenance entry. Preventive maintenance is carried out by customer service.

You must schedule preventive maintenance according to the information in the maintenance chapter of your machine’s operating instructions.