August 29, 2019 – by our support team

The hidden cost of doing nothing

Every vhf dental machine has low maintenance requirements. However, due to their many features and the nature of CNC manufacturing, they need regular cleaning and some basic maintenance.

As we know from experience, many support cases and machine repairs could have been avoided if the machines had been cleaned and maintained as required.

So while saving time and money by skipping cleaning and maintenance may seem very attractive at first glance, it may cause additional costs rather sooner than later.

Watch the video

YouTube video – When viewing this video, personal data is sent to YouTube, LLC, USA. Privacy statement

The top 5 maintenance sins

Not cleaning the collet chuck regularly or using too much grease

If you do not clean the collet chuck every week (or every 3 days for heavy users), your machining results will worsen over time and your spindle may get damaged. Why risk that the “engine” of your machine may fail?

If you use too much grease during cleaning, grease may get into the collet chuck. As a result, the collet chuck’s grip on tools may be weakened.

- Clean the collet chuck as indicated in the maintenance table of your machine’s operating instructions. (the linked text is part of the K5+ operating instructions, but it applies to all other vhf dental machines).

Not cleaning the working chamber as required or using compressed air

The working chamber contains many high-precision components. Machining residues that accumulate in the working chamber can impair the functionality of these components.

- Make sure that all machining debris is removed from the working chamber regularly. But don’t use compressed air as this will cause the debris to reach sensitive parts such as the linear guides.

- If you can remove the tool magazine(s) of your machine, do so during cleaning (e.g. R5, Z4, N4). Clean and grease the tool magazine as described in the maintenance chapter in your machine’s operating instructions.

Not checking the compressed air regulator daily for contamination

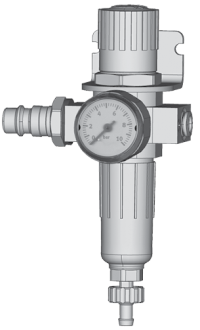

All current vhf dental machines but the Z4 are equipped with a compressed air regulator.

You can use it to regulate the incoming air, but the integrated water separator also serves as an indicator for contaminated air. Compressed air that is not oil-free or dry will quickly destroy the spindle and inner tubing of the machine.

- Check the water separator of the compressed air regulator daily for contamination.

Not exchanging the cooling liquid and cleaning the tank as required

If the cooling liquid or tank in corresponding machines is too soiled, the filters will no longer prevent the pump, tubes, valves etc. from becoming clogged. Especially if your machine is equipped with a relatively large tank, it is easy to forget to clean the tank and exchange the cooling liquid in time.

Not cleaning the nozzle plate regularly

The spindle of the R5, Z4 and N4 is equipped with a nozzle plate. You need to clean the nozzle plate regularly or else machining debris will clog the nozzles. As a result, the amount of cooling liquid injected into the working chamber will no longer be sufficient to cool tools and blanks.

- Clean the nozzle plate of your machine as described in the operating instructions.

Don’t panic, we got you covered

As already stated, the amount of required maintenance tasks is limited. You also don’t need mad manual skills to keep your machine in top-notch condition.

Our operating instructions contain a maintenance table in the maintenance chapter which conveniently lists all required tasks and the intervals. All tasks are described in detail and are richly pictured.

Example: Here is the maintenance table for the K5+.

So save your investment and get the best results out of your machine by regularly cleaning and maintaining your machine.